|

Sony Videoflight Facilities,

Sony - Sponsors and demonstrates the world's smallest and lightest videotape recorder (model PV-100), designed for the technological, industrial, educational, medical, sports and arts markets. Used two inch open reel tape in a 2 head helical scan system. The PV100 was adopted by American Airlines in 1964 for in-flight movies. Ampex was to sue Sony over this in 1966.

|

||||||

|

||||||

|

||||||

|

||||||

| Introduction

Videoflight, Inc., a wholly owned subsidiary of Sony Corporation of America, was founded in 1964. It was established to augment the sale of video tape recorders by the Industrial Products Division of Sony Corporation of America. Its primary business at the outset was to transfer first run films to Sony video tape for use by the airlines in Sony airborne entertainment systems. Within one year it grew from an initially simple installation to that shown in the photograph on page 2. It is probably today the largest film-to-tape transfer center in the world. Videoflight operates 24 hours a day, 6 days a week and produces a large quantity of high quality 2-hour and 4-hour tapes a month.Over the past two years the tape production techniques and the facilities for producing them have significantly improved through constant study, research and capital investment in the latest tape producing equipment. The story of Videoflight is the story of a pioneering organization. In 1964 when Sony first began airborne entertainment systems' development in conjunction with American Airlines and Pan Am, it became apparent that to assure the best possible performance of the entertainment systems, it would be necessary to ensure that the video tapes used were of the highest possible quality. It was necessary that this quality be realized on anyone of some 150 video tape recorders with any tape. "Interchangeability," as this characteristic is known, had never before been achieved to this degree and there were many who thought it was impossible. Sony realized that to achieve its high standards for tapes it would have to establish a new facility devoted entirely to tape production. For this purpose it invested a substantial amount in facilities and necessary supplies at Videoflight and hired highly skilled broadcast video engineers with extensive experience in video and audio (picture and sound) recording to man the new facility.For over two years these men and this equipment have turned out thousands of quality tapes each month from either films or other tapes while, simultaneously, continuously upgrading operating procedures and operating equipment until, today, Videoflight has achieved an unequalled and enviable position in the field of multiple video tape production.

|

||||||

| Tape Duplication

The management of Videoflight recognizes that there is now developing a vast demand for multiple copies of tape in such fields as medical education, sales training, cable television, industrial communication, home entertainment and general education. To meet this demand Videoflight has recently added equipment to permit the production of video tapes in any configuration and to any standard. For example, multiple tapes may now be made for the Sony EV-200, industrial Videocorder, the Sony CV-2000 series Home Videocorders, in addition to the Sony PV-120A, PV-120Al, PV-120U and video tape recorders of other manufacture.Special Requirements Where the source material is film and it is available to Videoflight for a very limited time (as happens with pre-release films) Videoflight combines the capabilities of its film chains and Allenized broadcast VTR to make master video tapes from which multiple copies may be made in the appropriate configuration (that is, 1/2, 1 or 2 inch video tape.) Videoflight has acquired extensive experience in making tapes from Cinemascope-type films. The necessary change in aspect ratio is achieved by skilled operation of the electroniccontrols in theVideoflight system while following the script from which the film was made. The essential portions of each scene are recorded for later reproduction.The Videoflight color film chain provides red, blue and green color output signals which may be encoded appropriately to permit recording on video tape.For example, excellent line sequential color recordings have been made at Videoflight on the Sony PV-series Videocorders. SECAM and other recording systems may also be used.

|

||||||

| Production Procedures

Incoming Inspection When source material is received by Videoflight, it is fully logged and passed to incoming inspection. The optical condition of the material (if it is film) or the magnetic condition of the source material (if it is tape) is determined prior to recording. If the material is technically inadequate for the making of a quality recording, the customer is advised and substitute material or an alternate approach is determined.Source Equipment When the source material is adequate technically, it is loaded on the appropriate source equipment-35mm film chain, 16mm film chain, 35mm color film chain, quadruplex video tape recorder or other-sound and picture levels are established and the source material is run with constant surveillance of both sound and picture levels by skilled operators as well as by automatic level-control electronic equipment.Playback and Quality Control When the recording is completed it is played back on the recording machine, as well as on other similar machines to assure good audio and video quality and interchangeability. If anyone of these elements falls below professional standards or if any other defect appears (such as tape drop-out), the tape is rejected by the operator and a complete re-run is performed. If the tape reaches the established quality. standard as far as the operator is concerned, it is passed on to the Quality Control Department where it is again put through rigorous tests.If it passes those tests it goes to the Shipping Department where its serial number, the addresses and the subject matter are noted. Logging of the total number of transfers made, whether shipped or not, and their dispositions are made accurately so that copyright owners can be assured that no unauthorized showings of the source material will be made.Re-Use of Tapes When tapes are returned for re-use, they are inspected for wrinkles or other defects, spliced if necessary, and bulk-erased before transferring new programs to them. Accurate records of tape erasures are also kept.

|

||||||

| Rates

Videoflight know-how and capability are now being made available to the industrial, medical, educational and entertainment fields at very modest charges. A comparison of the charges with those of conventional video "dubbing" studios, will indicate that they are lower. Such economies are possible because of the volume of business which Videoflight does in the airlines field. ,Rates are available on request. This Brochure is in the Video Technology Reference Section At SMECC Although it is undated it came in with a group of CV-2000 brochures form 1967. it seems to be in that time frame also or perhaps a year earlier. - eas |

||||||

From the Sony History Site http://www.sony.net/Fun/SH/1-11/h1.html

|

||||||

PV-100:

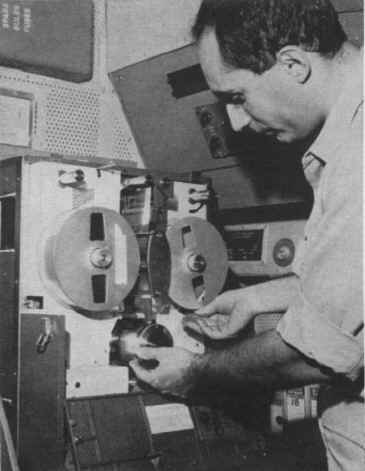

First practical VTR developed in 1962 by Mr.

Kihara at Sony Corp. Spec's: Black and white, mono sound, two inch

tape, 5-3/4 IPS, 8"? reels, 120 minutes record / playback time,

25" x 17" x 17" (hwd), 145 pounds. Shown here, being

threaded by an American Airlines technician, for showing an in-flight

movie on 26 video monitors in various locations about the plane. The

in-flight models of the PV-100 had the record electronics removed to save

weight and power consumption. Passengers could also select an external

view through a video camera, located in the nose of the plane, during all

phases of their flight. Info & photo:

Electronics World Magazine - March, 1965 PV-100:

First practical VTR developed in 1962 by Mr.

Kihara at Sony Corp. Spec's: Black and white, mono sound, two inch

tape, 5-3/4 IPS, 8"? reels, 120 minutes record / playback time,

25" x 17" x 17" (hwd), 145 pounds. Shown here, being

threaded by an American Airlines technician, for showing an in-flight

movie on 26 video monitors in various locations about the plane. The

in-flight models of the PV-100 had the record electronics removed to save

weight and power consumption. Passengers could also select an external

view through a video camera, located in the nose of the plane, during all

phases of their flight. Info & photo:

Electronics World Magazine - March, 1965

Courtesy Labguy's World www.labguysworld.com |

||||||