|

Microwave Heating In Freeze-Drying, Electronic Ovens, and Other Applications

by DAVID A. COPSON, Ph.D. Professor of Biophysics, Biology Department, Former Head, Food Research Laboratories, Raytheon Company. Chairman, Industrial Advisory Committee on Microwave Studies, Forum Corporation. Editor, Forum Review, Cohasset, Massachusetts. WESTPORT, CONNECTICUT THE AVI PUBLISHING COMPANY, INC. 1962 ©THE AVI PUBLISHING COMPANY, INC. CHAPTER 11

Development and Construction of Microwave Ovens

INTRODUCTION A microwave oven is a box or cavity which is generally rectangular in shape and designed for the purpose of heating food by a method known as microwave or electronic cooking. The essential components of the oven are illustrated in a cutaway drawing (Fig. 100) as seen from a rear corner. Microwave heating by definition selects frequencies which have wavelengths generally commensurate with the dimensions of food masses to be heated. The relative dimensions of wavelength and cavity at 2,450 megacycles are such that the cavity is several wavelengths on a side. This is regarded as a favorable design condition, although obviously it becomes difficult at lower frequencies and longer wavelengths still in the microwave region. The system is completed by placing food material in the cavity on an appropriate utensil, closing the door, and operating the controls. Heat generation within the oven is generally independent of the position of the sample. However, for two or more food masses, the uniformity with which heat is generated within them is a function of the quality of the oven. Ovens have been produced for this purpose since 1945 and the original concepts for this electronic approach to age-old cooking are attributed to Spencer (1949, 1950, 1952). Already familiar with the mass production of magnetrons during World War II, Spencer adapted them to cooking devices. Thus he inaugurated a new era in the preparation of food and set the stage for the involvement of cooks all over the world in (the matter of mastering) a radically different device. More or less simultaneously, others were interested in the development. For example, it was shown by Kinn and Marcum (1947) that various sizes and shapes of heating cavities could be obtained by varying the wave guide termination. Similarly, the effect of heating and thawing foods with microwaves was studied by Morse and Rivercomb (1947) at 1,050 megacycles. They first described the "runaway" problem wherein the food thawed at one point and attracted a disproportionate share of energy. In the early efforts, the Raytheon Company, the General Electric Company, and the Westinghouse Company were actively pursuing development programs in the United States. Raytheon selected 2,450 megacycles as a frequency for concentration while General Electric preferred to work with a frequency of about 915 megacycles. The U. S. Navy hoped to find a more appropriate method for preparing food in submarines and sponsored evaluations of ovens through the Bureau of Medicine and Surgery (Sussman 1947). They remained optimistic but respectful of the skills and special equipment involved.

FIG. 100. COUNTER TOP MICROWAVE OVEN Courtesy of Philips Tech. Rev.

A-Anode voltage transformer. EK-Cylindrical wave guide coupling. F-Suppressor filter. G-Oven. Gt-Oven door. H-Heater current transformer. K-Cooling fan. L-Exhaust fan. M-Air-cooled magnetron with ferroxdure magnets R-Mode stirrer. '

|

|

HISTORICAL DEVELOPMENT The development effort undertaken by Raytheon and centered on the "Radarange" remains the most intensive program to date. The array of microwave ovens in Fig. 101 illustrates the progression of models up to the year 1954. Under date 1945 is pictured a lightweight device for use in aircraft. It was capable of defrosting and heating eight ounce meals in aircraft from 10° to 170°F. (-12° to 77°C.) in one minute. In this model, the cavity is shaped like a drawer for which a pull handle is visible near the top of the cabinet. Aircraft meals have tended to depend upon the high quality and variety possible with ground catering facilities, supplemented by cabinets which keep the food hot aloft. However some version of this microwave heater may appear at another time as a part of a high speed, high capacity aircraft meal system. The 1946 model is a sandwich heater and the cavity is a removable box shown at the side. When this "cavity" was moved into position, the sandwich could be heated in a few seconds. This machine anticipates the fixed-load, short duty cycle principle which is seen today in microwave equipped vending machines.

First Cooking Model In 1947, the 1132 model or the "white range" appeared. It had an output of about 1.6 kilowatts with one water-cooled, permanent magnet magnetron. This was an extremely concentrated and heavy box of electronic hardware compared with the versions which appeared later. The microwaves entered from a U-shaped transmission line waveguide through an "iris" window of Pyrex glass on the rear wall of the oven just above the mid-point. This range introduced a "stirrer" or mode agitator which was designed to improve the distribution of heat. It consisted of two chromium plated back-to-back hollow hemispheres in the top of the oven. These rotated at about 2 to 3 revolutions per second with power coming from a motor and turn-table in the upper compartment. The magnetron was mounted with the antenna positioned vertically in the wave guide under the oven. It operated on direct-current power from a power supply that was designed to be highly protective for the magnetron. This model had a small oven and a high power output which tended to give great microwave field densities and to exaggerate any shortcomings in the distribution of heat. Accordingly, the first real acquaintance that many persons had with microwave cooking was marred by the uneven heating results.

Range with Adjustable Power Next, chronologically, comes the 1150 model which utilized two air-cooled QK-312 magnetrons in an oven which is huge by comparison. It measures 21 X 29 X 26 inches in height, width, and depth, and the two magnetrons are directly inserted into the roof of this oven. The oven has an opening which measures 14 X 29 inches, The range is shown under the year 1951. It has been in use since then aboard the liner "United States." The distinctions of this model included, first of all, the unusual power output -- theoretically over two kilowatts could be obtained. However, it was recommended that the cooking be done within a setting of 200 or 300 milliamperes of magnetron current. This meant that useful power between 1.1 and 1.7 kilowatts was available. These two magnetrons were cautiously under-rated, and the operator (who was most likely to be a chef in this case) was provided with a variac on the control panel. The recommended range of cooking speed on the dial for the variac corresponded with the range of 400 to 600 milliamperes, the total for the two magnetrons. Therefore, the chef was capable of changing the magnetron operation to suit his cooking needs and he could actually go lower than 200 milliamperes and higher than 300 milliamperes for each magnetron if he so desired, since the control was fully available. The energy supplied to the oven is dependent on the magnetron current which is, in turn, determined by the magnetic field and the voltage applied to the magnetron. The magnetic field is a permanent one, and for this case, the current is controlled by varying the voltage applied to the magnetron. This is accomplished by a line corrector transformer which operates the variac. The end result is an unusual flexibility in the cooking which gives a beginner a slow microwave heating process that minimizes any errors in estimation of the process time. Later, when he is skilled, he would operate closer to the "red" portion of the variac dial, obtain very fast cooking, and be able to process more food. Consequently, this model introduced good power, adequate volume, and very flexible control. However, there is still another feature which gives an insight into the practices in microwave cooking. The 1150 range was provided with a drainage hole located at the low point in a sloping oven floor. When this range was being developed, it had been observed that fat which melted downward from the roasts collected in the utensil. This fat was at least 100°F. (56°C.) cooler than drained fat in ordinary roasting and it had a tendency to keep the bottom of the roast cooled, shielded it from microwaves, and in general interfered with results. Thus, the stainless steel oven floor with its sloping surface could be used as a substitute for the utensil. The hole permitted fat to drain through a tube into a receptacle (accessible from the front of the range for emptying). The surface was easily wiped clean after use since this was a cool oven with no infrared heating. It was easily possible to roast 50 pounds of meat or more in one load in about two hours. The contribution of oven size was more in the direction of convenience and microwave performance than in capacity. However, some improvement in rate of cooking was obtained because the magnetron efficiency curve rises in this region of loading and operation. Commercial Models In 1954, an 1161 mode] appeared which was designed for commercial use in restaurants, hospitals, hotels, and institutions of this type. Microwaves were generated in this model by two QK-390 air-coo magnetrons adjusted to provide about 1.5 kilowatts for cooking heating. The oven measured 20 X 22 X 12 inches in width, depth and height and the magnetrons were again directly inserted into the top. The uniformity of heating in this oven reached the highest standand! of development up to that time. It was achieved by means of t dimensions, an improved stirring device with fan-type blades, and t use of two magnetrons and their locations. A choice for power input was provided by a switch for high, medium, and low setting's, , later, high, low, or off. At the low setting, only one magnetron was energized and the pattern of heating was much stronger beneath the tube than in the rest of the oven. The skills needed for actually cooking with this range rather than heating food only, tended to limit its use to carefully designed systems for food service or to simple standard-quantity heating operations. The size of the oven contributed to the performance even if it was not fully utilized with heavy loads. A smaller oven would not have heated small, randomly-placed loads as reliably. At first a ten-minute recycling timer was used but it w later changed to a 21-minute non-cycling one. In all cases, the cooling began when the "cook" button was pressed. However, with the ten-minute timer, the button had to be repressed after each ten minutes. There was an element of security in the shorter period, but was generally inadequate at 1.5 kilowatts. A companion oven with a single magnetron of the same designation was also available in 1954. It provided a smaller oven which measured 14 X 18 X 10 inches in width, depth, and height. The height in these cases was measured to the top of the door opening, and the were about two more inches available until the rotation circle of the stirrer terminated the useful height. The performance of the 1170 as this oven was called was clearly overshadowed by its bigger brother the 1161. The commercial users were often interested in the heating of eight-ounce prepared, refrigerated casserole or some equivalent load. In quick-service food establishments, the one minute needed for this heating in the large range was satisfactory, but twice this time (a required in the 1170) apparently seemed disproportionately longer. There were other benefits, however, in the 1161 including a superior pattern of heating with two magnetrons working into the larger space. Domestic Ranges Further development led to the domestic microwave ovens which were introduced in 1955 and 1956. With these models Raytheon became an original equipment manufacturer for a group of domestic range companies including Hotpoint, Westinghouse, Tappan, Kelvinator (American Motors), and Whirlpool. Power supplies and magnetrons were furnished to each company which designed its own domestic range around these components. Tappan, meanwhile, had pursued the development continuously and produced a series of designs which were called the 1180 models. In one 1180 model, a major change was made in the introduction of microwaves through a transparent oven bottom. This left the top of the oven free for other possibilities, such as the introduction of a broiler element for browning the top surface and sides of food. The transparent bottom had to be designed so that spilled fluids did not penetrate into the stirrer compartment and magnetron section which were just beneath it. At about the same time, attempts to introduce microwaves into an oven directly through the broiler indicated the feasibility of such a design. Simultaneously, a built-in version of the oven was visualized which was essentially a match for the conventional built-in oven. Behind the panel, on which controls were mounted, there was space for some of the electronic components, while the rest could be installed behind the oven.

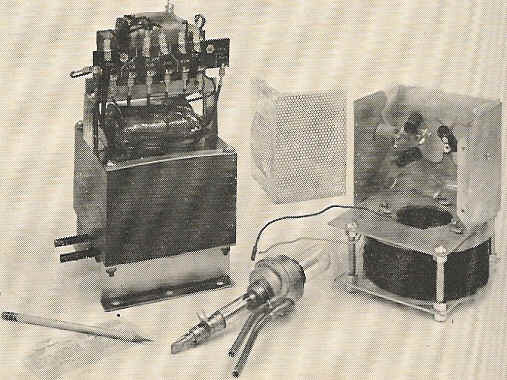

Magnetron Improvements Microwave cooking was introduced into many homes with ovens of this design and considerable experience was accumulated. Improvements in the magnetron were long overdue, however, since the value of the power supply and magnetron alone was greater than some complete conventional ranges which were readily available. When the range manufacturers had completed the cabinet and put the device in position for sale, its price was too great for wide appeal. Similarly, the magnetron performance was a critical factor in marketing these ovens because the tube was the heart of the oven. When it failed, there was no further microwave heating. There was a demand for an inexpensive generator and possibly one which could be replaced in part when it failed retaining, for example, the magnet. Also some components could be eliminated from the power supply by delivering alternating current to the generator: in a sense this would use the diode magnetron as the rectifier. It was also desirable to reduce, if possible, the warm-up time delay which was currently about 75 seconds. A new magnetron became available in 1960 which met many of these requirements and increased the power by 20 per cent. It was produced by Litton Industries, San Carlos, California and called the "Microtron"; one type, the L-3510, is a microwave heating unit consisting of a cw magnetron, a high voltage transformer, a filament an isolation transformer, and an electromagnet and filter assembly, These units are shown in Fig. 102 with a pencil included to suggest relative sizes. When assembled, the magnetron fits inside the electromagnet with the larger glass envelope passing further into a wave guide on which the whole assembly is mounted. The lines for the cooling water encircle the midsection of the magnetron and connect with the closed cooling system. Above the plate transformer is a terminal strip which is used by the service man when the range is installed. After he determines the line voltage available, he can compensate for variations in it by choosing the correct tap, The taps on the plate side of the strip compensate for variations from 208 to 240 volts while those on the filament side handle variations from 104 to 120 volts. The high voltage transformer is also connected to the cooling system as indicated by the connecting tubes at the base.

FIG. 102. MICROTRON, MICROWAVE POWER UNIT

Also shown are the magnetron circuit connections, filter assembly, and shield. These components are installed in position in the microwave oven power supply compartment as illustrated in Fig. 103.

Courtesy 0f Litton Industries FIG.103. MICROWAVE OVEN POWER SUPPLY COMPARTMENT The oven dimensions are 18 X 14 X 12 inches for width, depth, and height. This size permits top placement of such Units as: the wave guide; stirrer motor, drive wheel, and belt; direct-current power supply, test jack panel, and magnetron output power adjustment. In the rear of the oven, the water hoses connect the reservoir, pump, and cooled components with the radiator which is underneath the oven cavity. Forced circulation of air is provided over the radiator and out through the top compartment. Air may also be exhausted from the oven to prevent condensation during cooking. This would apply especially in an oven when only microwaves are used. Two new magnetrons were developed by the Raytheon Company for microwave heating; the QK707 and the QK904. The QK707,

FIG. 104. MAGNETRON QK707 WITH CLOSED LIQUID COOLING SYSTEM Courtesy of Raytheon Co.

Fig. 104, was used in place of the QK390 in microwave ovens such as the Mark III, IV, and V. It has an output of 0.8 kilowatt. Further development produced in 1962 the QK904 which is shown in Fig. 1,05. It incorporates many of the features deemed desirable for a heating type of magnetron. For example, it operates on unregulated alternating current as well as direct current for its 3.2 kilowatts anode voltage. It has a higher output which will bring single generator ovens up to 1.25 kilowatts.

DESIGN A microwave oven may be regarded as consisting of eight major components: (1) the power supply which draws electrical power from the line and converts it to the form required by the microwave generator; (2) the generator or power tube which is an oscillator capable of converting the power supplied into microwave energy; (3) the transmission section which propagates, radiates, or transfers the generated energy to the oven; (4) coupling devices which permit the

. FIG. 105. MAGNETRON QK904 Courtesy of Raytheon Co.

transfer of energy to the oven; (5) the distributor which rotates and scatters the transmitted energy through the oven, disturbing the standing wave patterns; (6) the cavity or oven which encloses the cooking food within metallic walls so that the distributed energy is reflected and intercepts the food from many directions with more or .less uniform energy density; (7) energy sealing or trapping structures which serve to retain the microwave energy within the oven confines during operation; and (8) operating and safety controls which allow selection of cooking conditions and interrupt the flow of power if necessary. In addition, auxiliary heat may be incorporated in the form of a broiler element or complete hot oven components. There are also subsidiary requirements for cooling the generator, the transformers, and other electrical components which dissipate heat. Provision is usually made too, for exhausting the oven of cooking vapors, and for visual and audible indicators of the end of the cooking cycle. The character of the eight components has already been considered along with various topics; for example, the dimensions of the cavity compared to the wavelength and cavity design were taken up in Chap

ter 5. It was shown that the length of a cavity wan should be greater than a half wavelength and any multiple of a half-wave in the direction of propagation win satisfy the requirement (Ramo and Whinnery 1944). The cavity can then resonate and microwave energy can pass from the wave configuration established in the cavity to the food. The rays then attenuate since they are partially absorbed in their transmission through the food; they impinge on metal cavity walls and

' reflect again and again until the energy is used up in the heating process. The number of modes which can be supported in the cavity II was given as a function of the volume of the cavity. Skin depth, current at the walls, impedance concepts, cut-off frequency, and the Q, of the cavity were defined. WAVES, FIELDS, AND FOOD The disappearance of energy from the waves in the cavity depends on the amount of energy present and on the amount of absorbing material present. The direction of the microwave alternates from and to the generator at the rate defined by the frequency. Therefore, the system is oscillating and oscillations are usually spoken of as damped if something absorhs some of the energy. The change in energy with time would be described in an exponential manner (familiar to biologists in deactivation processes) where the change at any time depends on the amount of the variable, in this case, energy left in the systeml For resonant cavities, Q is the quality factor

Q = Wo (energy stored in the circuit) average power loss

where Wo = l/VLC and L is the inductance and C is the capacitance. Also,

Q = TT (energy stored in the circuit) energy lost per half cycle

From these ratios, the meaning of a "high" Q or "low" Q cavi,tYmay be understood. In the high Q cavity, there will be considerabIere active and circling power, and a high SWR in the oven which Could then be considered as efficient for heating. .The rigorous definition of cavity dimensions in terms of wavelengths IS 2 AO= V (mlax)2 + (n/ay)2 + (plaz)2

w AD is the free space wavelength, , y, are rectangular oor ats for the box dimensions, and , n, are integers. Usually the Iheight, width, and depth will differ considerably. This analysis is for the high Q cavity with no damping. The curves for resonance would have sharp peaks (in the lossless cavity) but in the highly damped one as when food is heated, the resonance maxima are not sharp. The cavity will have broad resonance peaks with heavy loads and more narrow ones with light loads. The effect of broadening these peaks is to stabilize the field distribution and thus the load impedance of the generator (Schmidt 1961). Loading the oven with food ,is favorable for generators but now there is no longer a high Q cavity. Itdevelops that in such cases, one is working with a high quality cavity in which the Q has been lowered (by the food). Broadening of Resonant Peaks If the energy is carried by the modes and distributed to the food more or Jess by rays, this broadening of resonance peaks begins to ap'pear as a phenomenon of expanding resonance points in the frequency space until they more or less meet, so that any initial ray direction is permitted (Rapuano and Smith 1955). A mode stirrer meets the need for distributing the incoming energy in these various directions. For the food, this means that it is being irradiated from many directions. The stirrer is effective if it helps the cavity to fill with energy ,so that the heating of the food will be independent of position. It also will increase the number of resonances. The idea is to use dimensions, reflecting sides, and a stirrer to pro duce an oven in which a great many different modes with overlapping resonance bands may be excited. If the cavity is filled with food, the reflections are diminished, this effect depending upon the frequency and associated penetration. Therefore, if the stirrer is to be most effective, it should be located between the generator and the load (Smith 1957). The stirrer is an important feature of the oven but much work ,remains to be done before its action is fully understood. It is best to I'ook at the stirrer as a tuning device and to consider ways and means oftuning the cavity for maximum energy distribution and utilization under the conditions to be met in loading. The stirrer, as one of a number of tuning devices, such as rotating antennas, food turntables, "paddle-wheels" and vibrating cavity walls, can be evaluated by the effect it has on the distribution of energy. Generally, this mode stirrer will look like an air-circulating fan but closer inspection shows that the blades are designed for reflected

energy rather than moving a column of air. The blades may be pitched at an angle of about 450, the angle depending upon the relative position of the magnetron probe. That is, if you assume that ,the energy is to be directed vertically when it: strikes the stirrer blade, and the main flow of microwave power comes at the blade at an angle of 60° with respect to the vertical axis of rotation, a solution of the optical angles involved gives a blade which makes an angle of 30° with the vertical axis of rotation (Smith 1957). Two fans were used to distribute the energy in the cavity by Becker and Autler (1946). They were showing that water vapor has a max. imum absorption of energy at a wavelength of 1.34 centimeters. They were not primarily interested in stirrers. A large copper fan was used at the top and a smaller one at one side wall. The energy distribution at different walls was very uniform. The energy will a]so be caused to reflect from an inclined plate at the end of the wave guide according to Blass (1952). The angle of inc]ination is 45°. With a stirrer in front of such a sloping plate, the blades may be at an angle of 45° with the rotation plane of the fan. Fig. 106 shows an oven with the stirrer and an interna] reflector in use with a cylindrical wave guide and a broiler unit. The broiler can be considered as an oven structure which absorbs a slight amount of energy. The mounting is necessarily smooth where the wall is penetrated to avoid arcing there. There will be oven situations with wave guides propagating energy into the cavity; another type has a dipole radiation pattern from an internal antenna; and there is also the type which gives propagation from the AI4 radiating probe of the generator when it is directly inserted. Even without the stirrer, the beam from a wave guide can be sent out into the cavity from metal reflectors (one wavelength long) so that the energy will have several reflections before it returns toward the source. Instead of using reflectors, the shape of the oven itse]f can be designed for this effect. When the generator probe is directly inserted, propagation toward the load is improved by placing it at the intersection of two lines which are parallel to the center lines of the oven but moved from oven center by an eighth wavelength at the operating frequency (Blass 1952). This combination of sloping even sides and displaced magnetron probes may be seen in the construc. tion of the large 1150 model which is discussed on page 264. HE Horn and Cavity When a horn attachment can be used at the waveguide termination, a broad energy beam in the H-plane is obtained which can be

Courtesy of Philips Tech. Rev.

FIG. 106. POSITION FOR MODE STIRRER IN MICROWAVE OVEN AT 2,450 Mc R-Mode stirrer. Gr-Broiler grill. M-Microwave source. Refl-Reflector plate. G-Cavity. PI-Oven tray. Dimensions 440 X 400 X 360 mm. (17.3 X 15.7 X 14.2 in.). 'distributed as it reflects on the sloping oven sides or strikes the rotating reflectors. Then if the horn is designed as are HE horns with 'both magnetic and electric flares, it becomes possible to consider a stirring device of the paddlewheel or fan type in the horn itself. In this way, the energy is certain to be disturbed before it gets to the oven, and for a small load and small oven, this might be the method of choice. Fig. 107 shows the method used by Haagensen (1958) for this design. His concept also included a provision for matching energy smoothly into a container of food. He used a Pyrex glass floor in the cavity: this in itself was transparent to microwaves, but had a quite different impedance from the horn feed. When a container such as a

ceramic or glass casserole dish is placed on the g]ass floor, the Gombined thickness produces a good impedance match into the foodin the casserole. In optical terms this wou]d give a coupling iris or a sharp discontinuity in the impedance at the container location. Then the food would draw most of the energy and heat effective],y. The construction also protected the magnetron from damage due to overheating or mode shifting by the use of a four spoke radial aperture in the top of the cavity. When the generator was accidentally energized with no load, the microwaves passed harmlessly,

FIG. 107. HE HORN AND PADDLEWHEEL STIRRER IN SPACE PROVIDED BY THE DOUBLE FLARE (Two VIEWS) A. Transparent glass floor. B. Four spoke radial aperture covered by absorbing block.C. Paddlewheel stirrer. out these coupling slots. A functional and attractive design' was provided for the door (not shown) in which energy containment was assured by a grill with openings less than a half wavelength. In this oven, there were a number of innovations in the use of materials which combined special mechanical and electrical requirements. For example, the Pyrex glass tray has a thickness much less than a quarter wavelength so that with its dielectric constant quite removed in value from the air in the horn, it presents an impedance discontinuity to the energy propagating from the transmission line. The safety slots in the top are about one-half wavelength long. The combined thickness of containers and Pyrex tray is a quarter wavelength for the radiated and transmitted energy. Both have a dielectric constant of about six (or about equal to the square root, of the dielectric constant of the food multiplied by the dielectric Constant of free space). At 2,200 megacycles, the thickness for the combined

dielectrics (tray and container bottom) would be slightly less than one-half inch. 'The stirrer rod being in the microwave field is constructed of an insulator (nylon) for non-arcing, and nylon is also chosen for some of lUhe studs and guides for the door. The stirrer blade contains a slot and 'resembles an asymmetrical paddlewheel in the "flowing energy stream." The asymmetry and slot combine to reduce the cyclical -rises in the standing wave ratio and also prevent self-heating of the mode stirrer.

FIG. 108. POLARIZATION STIRRER Other Tuning Procedures Hall (1952) has given six objectives in the design of an effective microwave oven: (1) uniformity of distribution of microwaves in the device; (2) uniformly integrated microwave heating pattern; (3) maximum use of the input power in heating food; (4) uniformity of heating obtained from periodic change in the field distribution; (5) continuous changes in the mode of the waves in the cavity and obtaining a uniform heating from changing complex modes; and (6) heating food masses uniformly where the wavelengths are those of microwave frequencies. He recommended that the oven dimensions should differ, for example, by a quarter wavelength in magnitude. The favorable effect of this asymmetry on the number of modes that will exist in a given range of frequencies is enhanced by introducing the power at a point displaced from the center of one wall. Most of the ovens which have been described have illustrated this feature.

The maxima and minima in the fields are therefore moved around in the cavity but they persist. The Hall oven is visualized in the 1132 model which employed the wave guide feed through an iris in the rear wall. The insertion was asymmetrical and high with respect to the rear wall but on the mid line. As a means of disturbing the modes, he a]so described a piston with a flat, square surface reciprocating in the top of the cavity. The piston area was such that a side was three-fourths of the comparable oven dimension. A slow rate of oscillation was prescribed for this member (about 75 per minute). Hall also described a type of mode shifter which includes a provision for polarizing the energy. Two grids of rods were used on different levels. This stirrer may be visualized as replacing one of the others which have been described and it is shown in Fig. 108. Each quadrant could be expected to yield a different effect on waves approaching it. In the third quadrant (clockwise), for example, the conducting rods will reflect both horizontal polarization components from the stirrer-that is, both the component of the waves which is parallel to dimension Wand that parallel to dimension D. Therefore there is a dif ferent polarization, reflection action in each of 4 quadrants. First there are no reflections, then one horizontal polarization, then both horizontal polarizations, and lastly, on]y one again. In addition, one would have the action of waves passing on for a wall reflection beyond the stirrer. The disc]osure (Hall 1952) explains the effect in terms of the distances travelled by the waves and the perturbation is of the distances. At high microwave frequencies which result in few transmissions through the food, quick absorption, and short penetration, this stirrer participates to a lesser extent in the perturbation. When the stirrer is interposed between food and microwave source however, as in the HE horn, there would always be some perturbation.

BIBLIOGRAPHY BECKER, G. E., and AUTLER, S. H. 1946. Water vapor absorption of electro magnetic radiation in the centimeter wavelength range. Physical Rev. 70, 5 and 6, 304-307. BLAss, J. 1952. Heating apparatus. U. S. Pat. 2,618,735 Nov. 18. HAAGENSEN, D. B. 1958. Electronic heating apparatus. U. S- Pat. 2,827,537 March 18. HALL, W. M. 1952. Heating apparatus. U. S. Pat. 2,618,735 Nov. 18. KINN, T. P., and MARCUM, J. 1947. Microwaves and their possible use in high frequency heating. Electronics 20, No.3, 82-90.

MORSE, P. W., and RIVERCOMB, H. E. 1947. UFH heating of frozen foods. Electronics, No. 10,85-89. RAMO, S., and WHINNERY, J. R. 1944. Fields and Waves in Modern Radio. John Wiley and Sons, Inc., New York. RAPUANO, R. A., and SMITH, R. V. 1955. Design considerations of microwave ovens. IRE Convention Record, Part 9, 3-9. SCHMIDT, W. 1961. The heating of food in a microwave cooker. Philips Tech. Rev. 22, 3, 1960-61. SMITH, R. V. 1957. Heating devices. U. S. Pat. 2,813,185. Nov. 12. SPENCER, P. L. 1949,1950,1952. U. S. Pats. 2,480,679; 2,495,429; 2,593,067; 2,605,383. SUSSMAN, L. 1947. Evaluation of electronic cooking device for submarines. Bur. Med. Res. Proj. No NM 001 016, Medical Res. Lab. Report 116.

|

|

|

|

Wonder if the microwaves came out the sides... - E. Sharpe.

|