|

|

ITE - Innovative

Television Equipment

|

| FROM AN ADVERTISEMENT HANDED OUT BY ITE THAT

WAS REPRINTED WITH PERMISSION FROM: "ON LOCATION MAGAZINE" THE

FILM & VIDEOTAPE PRODUCTION MAGAZINE

Equipment

Innovative Television Equipment

Taking A bITE Out Of The

Camera Accessories Market

By IAIN BLAIR

Bert Rosenberg, President of ITE and chief design engineer.

The three-letter logo, ITE, on the side of the company's world

headquarters in Woodland Hills, Calif., may not have the familiar ring of

IBM or RCA, but in its own way it spells out a success story that is no

less impressive than those of such globally influential super-companies.

For ITE stands for Innovative Television Equipment, one of the country's

leading operations in both the design and manufacture of camera support

equipment. And even if you don't recognize the name, the chances are

you're using one of their camera heads, tripods, dollies, pedestals, carts

or other accessories in a wide array of applications ranging from

broadcast and industrial to educational and closed-circuit television.

The company was formed in the late '60s by president Bert Rosenberg and

vice president/treasurer Stanton Hollingsworth, who originally met while

working for Houston Fearless, a well-known support equipment manufacturer

at that time. "I was there for some 12 years before teaming up with

Stanton and leaving to form ITE in May 1969," explains Rosenberg, who

graduated in engineering from UCLA in the '50s. "It just seemed like

a natural move for both of us, especially as the marketplace was wide open

at the time and there were an enormous amount of changes taking place in

the business. You've got to remember that even back then, there were vast

reductions in the weight of cameras along with all the new, emerging color

technology and lower cost equipment, and it opened the doors for

innovations and changes in the support business as well."

"Bert had seen the weight of a television camera drop

dramatically, from over 300 pounds down to 150 pounds, while we were still

at Houston Fearless," comments Hollingsworth, "and realized at

the same time there simply weren't any new pieces of camera support

equipment out on the market to deal with such developments. So we sat down

and came up with a plan and a clear-cut objective to create a whole new

line of support equipment to service the emerging lines of low-weight,

lower-cost color television cameras."

"The broadcast support business is a very small, tight fraternity,

and no one seemed to have a handle on these or any other future

developments," continues Rosenberg. "So when we went ahead and

formed ITE, we got a lot of initial encouragement and enthusiasm from all

the big boys at the major camera manufacturers. It's always been a good

balance, as my background as a mechanical designer and engineer is

complemented and balanced by Stanton's training as a financial expert and

CPA - those were the basis of the company, making sure we covered both

ends of the business."

A few products to start

Having struck out on their own, Rosenberg and Hollingsworth decided to

test the waters by initially designing and manufacturing just three or

four products. "I sat down and designed a studio pedestal, a pan and

tilt head, a tripod and a dolly

that was our complete line. We also started by getting all of these

manufactured by an outside company," he adds. By contrast, today, ITE

manufactures over 50% of its product line on its own premises, and that

line has expanded to over 85 products - "so many, we just stopped

counting," laughs Rosenberg.

Despite such impressive statistics, it wasn't always an easy road for

the two partners, as they willingly admit. "All that initial

enthusiasm and encouragement from the major camera manufacturers

evaporated pretty quickly," says Hollingsworth. "After about

half an hour!" recalls Rosenberg. "Of course everyone is very

wary of dealing with a brand new company, even if they know your past

record is good," he continues. "And if someone's going to spend

half a million bucks on cameras, they're not going to take many chances on

the heads turning out to be duds. Consequently, the first few years were

extremely rough for us. It was very slow, and things weren't helped much

when we were also hit by a very bad recession in the early to mid-'70s.

"In fact, I remember a time when we were sitting on some 75

pedestals stacked out at a warehouse at LAX that were just collecting dust

and taking up an awful lot of space," recalls Rosenberg.

"Business was so slow that we seriously considered selling them off

cheap as seaanchors! Fortunately, things turned around in the nick of

time, and our tenacity and stubbornness not to give in suddenly paid off.

And since then, we haven't looked back. But we've never forgotten those

days of struggle either, and I think that's always helped us concentrate

on the value of good service and the highest possible quality of

product."

Much of ITE's success is due to sound, long-term financial planning, as

Hollingsworth explains. "When we started, we knew that the expense of

manufacturing our own prototypes would be prohibitive, and that would

severely limit our ability to experiment with a design. So we immediately

began looking around for the most cost-effective methods of manufacturing,

and after extensive research, we decided on opening up an Australian

company for the simple reason that at that time, one tooling hour was

costing just under $4, while in the U.S. the same work was costing closer

to $40 - ten times as much as in Australia. So it was primarily an

economically motivated move, which then allowed us the luxury of being

able to tryout various prototype designs at a relatively low cost.

"We basically go through three prototype stages," reports

Hollingsworth. "We start with the engineering prototype, in which

Bert designs a new product to specifically accommodate a new piece of

camera equipment. We'll then produce five or 10 of these prototypes and

then choose between six and 10 dealers to test them, and see what comments

and suggestions they have to make.

"The second stage is the redesign process," he continues.

"We incorporate all of these ideas and changes, and then do a sizable

run of the product. For instance, if it's a studio pedestal, we might make

10 to 15. If it's a tripod, the figures would be closer to 25 to 50. We

then distribute those to the field as finished products, but we also track

them all very carefully. We make a point of following up by both mail and

phone calls to get more comments and suggestions - anything to add to a

final evaluation of the product."

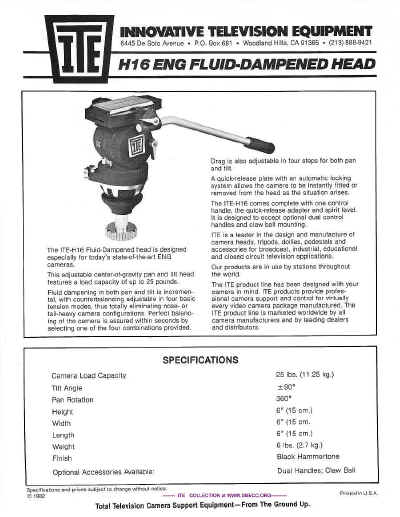

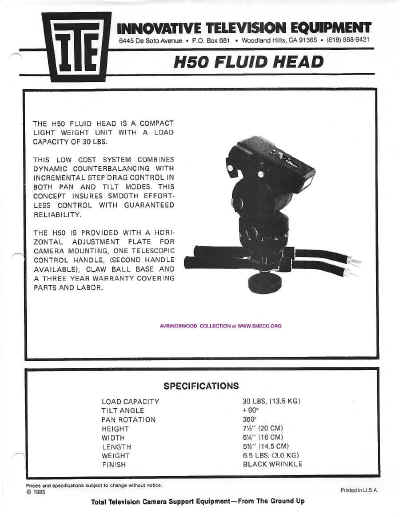

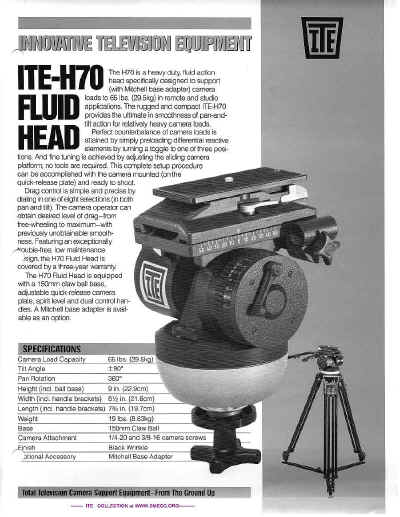

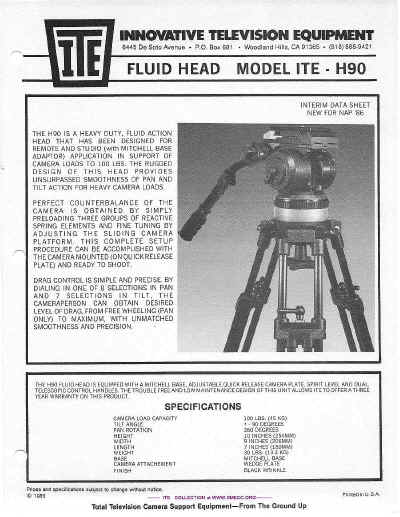

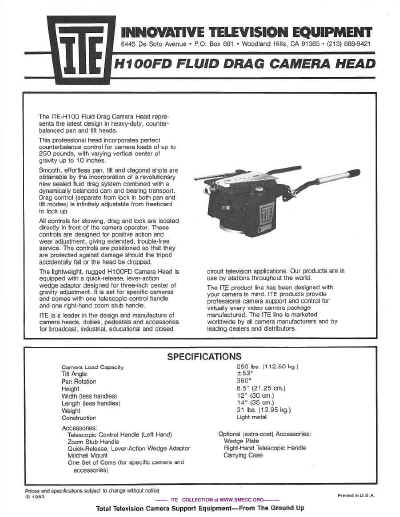

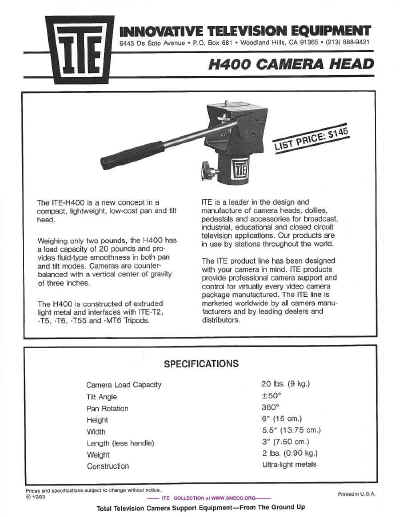

ITE markets nearly 20 different types of heads,

ranging from their top-of-the-line ITE-100 Hydrocam model, which

includes dual handles and wedge adapter, down to their ITE-H30 fluid

head model. All models are equipped with either single or dual-control

handles, and the single-handle models may also be ordered with a second,

optional handle. All their fluid and hydro models include an integral

spirit level, and like the tripods, are all finished in black wrinkle to

reduce light bounce to an absolute minimum.

"This process then leads to the final design, which is basically

then chiseled in granite," adds Rosenberg. "By this point, it

has to be absolutely right in every possible respect, because this final

design will have a life of between 10 and 15 years. And at this stage of

the product, we also commit to more expensive tooling and permanent

casting, etc. And, of course, we now also update and retrofit that first

production run - which, in reality, was a prototype run.

"This three-part method hasn't changed at all over the 16 years of

ITE's history, so it definitely works," Rosenberg continues.

"But on the other hand, the time taken to get through all three

stages has increased dramatically. We used to be able to design a

completely new product, do all the testing, and get it out there in a

relatively short time period, perhaps within one year in most cases. But

today, it usually takes a good two years to complete the same steps - for

a number of reasons. For a start, there's the increasing sophistication of

the products themselves, and the increase in sophistication of designs

requires increased sophistication in the tooling and manufacturing

processes. On top of that, there's been an enormous increase in the number

of dealers now working in the marketplace out there."

Widespread dealer network

"When we started in the late '60s, we only really dealt with three

big companies: RCA, General Electric and Visual Electronics, and they

represented over 90% of our total business," points out Rosenberg.

"But today, it's a very different scenario. You now have 11 camera

manufacturers and they represent a mere 20% of our sales. The reason for

this huge change is that those camera manufacturers now sell primarily

through dealers. Now, I do spend time talking with Ikegami, Hitachi,

Philips, Sharp, Sony and others, but the reality of the business today is

that it's all done through the dealers."

Because of this swing, ITE now spends a lot of time talking with the

camera manufacturers for their basic input on design issues, says

Rosenberg. "Their input is extremely important for both our

endproduct and our relationship with the dealers. We now have a widespread

dealer network consisting of almost 200, right across the country. It

averages out to about four per state, although obviously that number is a

lot higher in the large urban areas such as Southern California,

New York, Texas and Florida. In fact, our best area is the Southeast,

stretching from Texas to Florida and up the East Coast, and we think

that's partly due to the fact that a lot of production facilities either

moved there or set up operations in those areas in recent years."

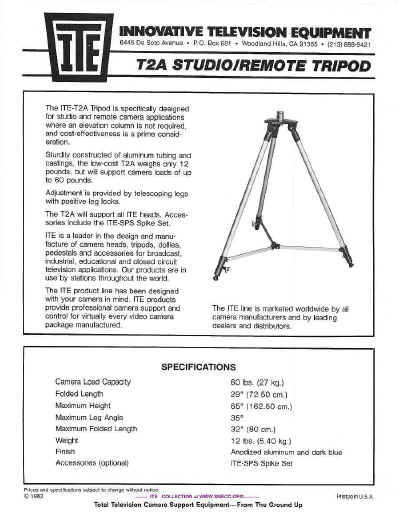

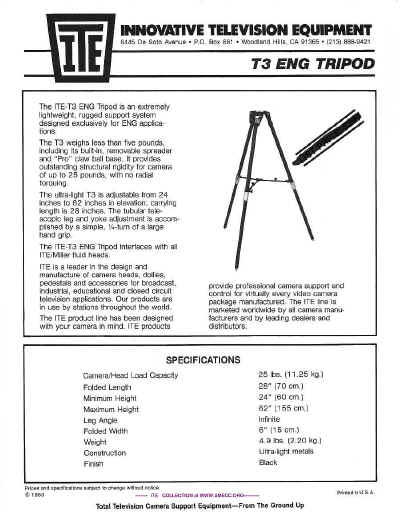

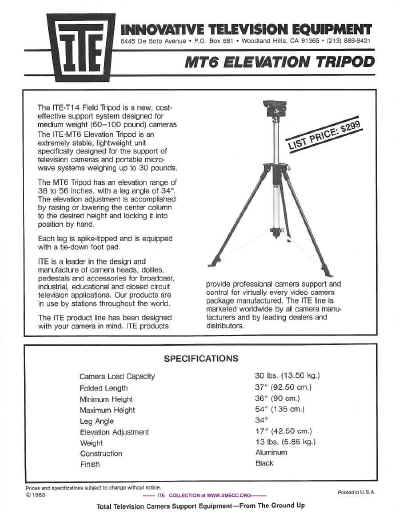

As proof of their enormous success in all areas throughout the country,

Rosenberg and Hollingsworth have some pretty impressive sales figures at

their fingertips. Over the past 16 years, ITE has sold over 30,000

tripods; 19,000 dollies; 6,000 studio pedestals; and a staggering 35,000

pan-and-tilt heads - fluid, cam and torsion. Their current list of

professional broadcast and audio/video closed-circuit television products

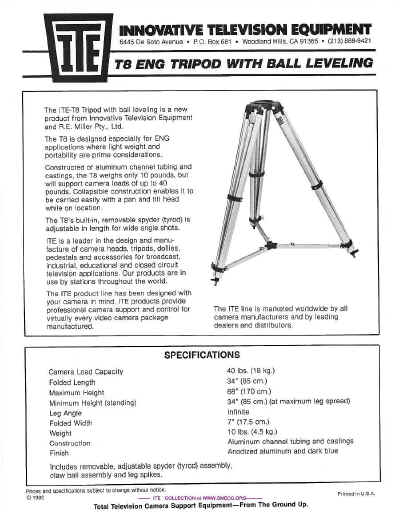

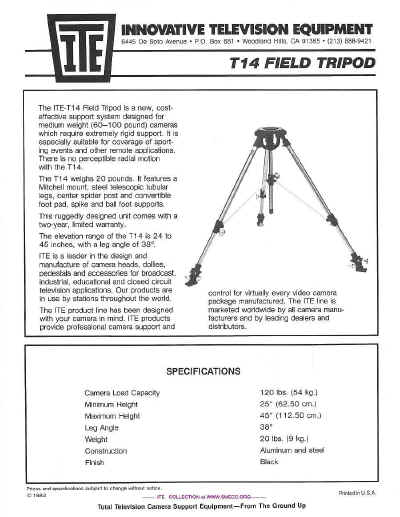

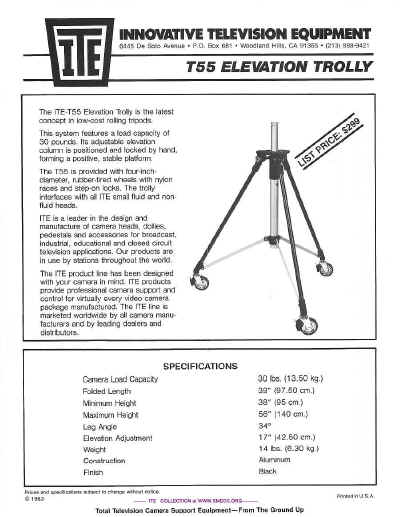

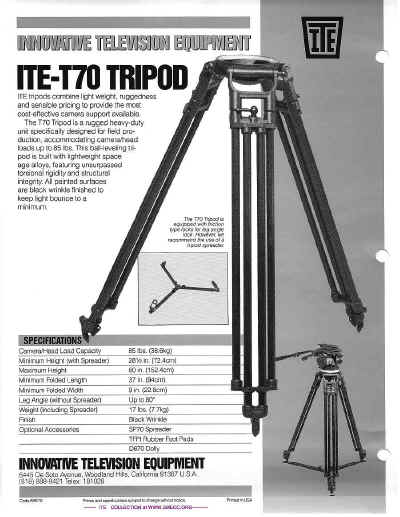

includes a wide range of tripods, from the camera-load capacity of 10

pounds for the ITE- T30 model to the 250-pound capacity of the ITE-MT1

model; they all combine lightweight and ruggedness of design, and are

offered in a wide number of ball leveling, elevation and non-elevation

models.

ITE markets nearly 20 different types of heads, ranging from their

top-of-the-line ITE-100 Hydrocam model, which includes dual handles and

wedge adapter, down to their ITE-H30 fluid head model. All models are

equipped with either single- or dual-control handles, and the single handle

models may also be ordered with a second, optional handle. All their fluid

and hydro models include an integral spirit level, and like the tripods,

are all finished in black wrinkle to reduce light bounce to an absolute

minimum.

The company offers seven studio pedestals, including its new ITE-P2

pneumatic model. "It's essentially the same as our very

successfulITE-P1 model," explains Rosenberg, "except that in

response to today's increasing use of low and ground-level camera angles,

we've further reduced the minimum height from 29

inches down to 26 inches. At the same time, we also increased the diameter

of the steering wheel from 26 inches up to 30 inches for easier handling

and maneuverability. So you can see we're constantly updating and

improving models to cope with a marketplace that's constantly changing.

We're not involved in the consumer market at all, we're purely in the

business of professional broadcast, industrial and closed-circuit

television applications, and our clients are always looking for some new

capability as the basic camera technology moves into new areas."

A cut-throat market

Rapidly changing camera technology over the past few years has helped

turn the camera support equipment business into a highly competitive and

cut-throat market, Rosenberg goes on to point out in some detail.

"You only have to look at the figures since the early '80s - some

five years ago, ENG and EFP camera systems were selling for as much as

$30,000, and the average cost of a tripod and head was around the $2,500

mark. But since then, the market has changed dramatically, and prices have

dropped incredibly. Camera systems are now selling for around $8,000, and

not only are they so much cheaper, but they also offer even higher-quality

pictures, etc.

"Now, I don't think camera prices will drop much lower - there's a

cutoff point where it changes from being a bargain to a suspect piece of

equipment," continues Rosenberg. "But at the same time, those

price drops have had a tremendous effect on our products, which after all

are inextricably bound up with camera systems. Today, that same tripod and

head pack age sells for just $700 - simply because no one's prepared to

pay more, although they expect and demand the same quality, etc. And we

try to give them the same quality."

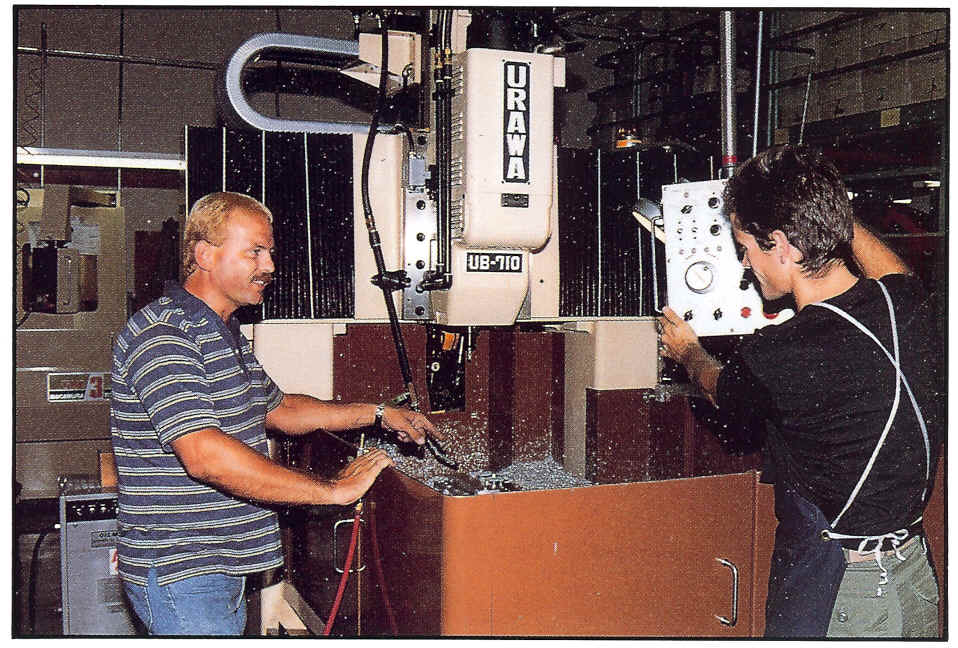

Rick Low, ITE's Manufacturing Manager (left) checks the output of one of

the numeric-tape controlled automated tooling machines.

"So this means that there's a great need to keep adjusting to

these changing market conditions," comments Hollingsworth,

"because if you don't, you're out of the market. We constantly have

to balance these economic factors with quality control factors, and it's

not easy. However, despite all these potential problems, our overall

volume of sales has been steadily increasing over the years," he

continues. "This is due to a number of factors. For a start, ITE has

much better market penetration today, and our products are pretty well

known everywhere; people know the sort of quality and service they'll get

with our products.

"Secondly, it's basic psychology that as prices drop dramatically

on a piece of equipment, the user tends to treat that equipment with less

care and attention to maintenance," he points out. "If you have

a $30,000 camera, you're going to look after it a lot better than an

$8,000 system, and that's why there's a much faster turnover in camera

equipment today. The same thing also holds true for camera support

equipment. For instance, there's not really a lot that can go wrong with

one of our tripods or heads - they're designed and built to last a long,

long time. The factors that do contribute to obsolescence are a mixture of

sheer physical wear-and-tear in the field, and above all, the changing

requirements of camera systems themselves. Weight factors have changed

incredibly over the years, as have basic design factors - and that means

the balance of the camera, or the vertical center of gravity -

consequently affecting critical design considerations for camera support

equipment.

"Finally, overall falling prices now mean that many companies can

afford to buy

two sets of tripods and heads, and use one set as a backup," adds

Hollingsworth. "It also means that many smaller companies who

previously simply couldn't afford in-house television capabilities are now

able to do so. Obviously, our primary market and sales are still in the

professional broadcast marketplace of both network-owned-and-operated

stations and the independents. We pretty much cover the whole field of

those 1,100 operations, and in some areas such as the Southern states,

we're particularly big."

Wide range of clients

"We also cover the whole spectrum of industrial clients, ranging

from the giants like IBM, Sears Roebuck, Mobil Oil, Chase Manhattan and

General Motors to hospitals and medical facilities, religious

broadcasters, etc.," reports Hollingsworth. "And last but not

least, we also cover the entire cable television marketplace, including

pay-TV, as well as a host of universities and colleges. Educational

training is also very big, and religious programming stations are a

particularly impressive growth industry today - they all have their own TV

studios, which are fully equipped with the latest technology." With

its aggressive marketing strategies and successfully expanding

marketplaces and clientele, ITE today operates plants in both Southern

California and Brisbane, Australia, with a third recent addition located

outside Tokyo, Japan. "We employ 23 staff at our 16,000 square-foot

facility here, and another 17 staff at our Brisbane 17,000 square-foot

facility," reports Rosenberg. "Meanwhile, our operation in Japan

currently produces some six products for us which they manufacture with

our design input, etc.

"We're pretty excited about the future," sums up Rosenberg.

"ITE is expanding in all areas, including the European and Asian

marketplaces. We've established

ourselves through sheer dependability and longevity- and we feel that

our products are of high quality and competitively priced (even though

competing in a foreign market). And we always deliver as required.

"On top of that, we're also planning to diversify into other areas

in the near future," he adds, "and not necessarily in the camera

support business, although it will be allied with it. We'll have something

of an electronics nature to unveil at next year's NAB show. But beyond

that, we're keeping it all under wraps right now."

Whatever surprises ITE has in store, it seems certain that this small

but tough company, which has already successfully carved itself a very

healthy slice of the camera support equipment pie, is looking at a bright

future indeed.

ITE Is headquartered In a modern 16,000 square foot facility In

Woodland Hills, CA.

HUGE PHOTO OF THE ONE ABOVE - CLICK TO SEE LARGE!

HUGE PHOTO OF THE ONE ABOVE - CLICK TO SEE LARGE!

ON LOCATION The Film and Videotape Production Magazine, October 1985

|

| |

|

INNOVATIVE TELEVISION

EQUIPMENT 6445 De Soto Avenue

P. O. Box 681 . Woodland Hills, CA 91365 . (213) 888-9421

P1 PNEUMATIC STUDIO

PEDESTAL

The ITE-P1 Studio Pedestal is the first and only

camera support system to be designed to meet ASME pressure vessel safety

codes, It incorporates computer-assisted design parameters and offers a

virtually leakproof pneumatic

counterbalance system for totally safe operation.

The counterbalance system utilizes fingertip control and handles camera

loads up to 290 pounds through an elevation range of from 29% to 51

inches. Vertical and horizontal movement is controlled by the

26-inch-diameter steering wheel.

Both crab and tricycle steering is provided. Rolling

resistance is held to a minimum by use of dual gimbaled

eight-inch-diameter wheels at each corner. Each wheel assembly has its own

adjustable cable guard,

The P1 counterbalanced Studio Pedestal is

constructed with a cast aluminum base for light weight and structural

integrity. The state-of -theart steering and bearing system provides trouble free

operation and ultra-quiet performance,

The P 1 Pedestal interfaces with all ITE pan/tilt

heads,

ITE is a leader in the design and manufacture of

camera heads, dollies, pedestals and accessories for broadcast,

industrial, educational and closed circuit television applications, Our

products are in use by stations throughout the world,

The ITE product line has been designed with your

camera in mind. ITE products provide professional camera support and

control for virtually every video camera package manufactured, The ITE

line is marketed worldwide by all camera manufacturers and by leading

dealers and distributors.

SPECIFICATIONS

Camera Load Capacity - 290 Ibs, (130.50 kg,)

Minimum Height - 29,5" (73.75 em.)

Maximum Height - 51" (127.50 em.)

Air Pressure - Pressure relief valve opens

at 200 PSI representing the

equivalent overload condition of 300 lbs, (750 kg,)

Minimum Doorway

Clearance - 30" (75 em.)

Wheelbase - 28.5" (71.25 em,)

Wheels - Dual, 8" (20 cm,) diameter

cast aluminum

with polyurethane tires

Cable Guard Adjustable from 1/8" (0.31 em,)

to 1" (2.5 em.) above floor

Construction - Cast

aluminum structure with steel tank and outer column to

ASME Pressure Vessel Safety Code; aluminum center column; vinyl coated,

26"

(65 em.) diameter steering wheel

Finish - Black wrinkle hard coat

Prices and specifications subject to change

without notice, © 1983

Total Television Camera Support

Equipment-From The Ground Up

Printed in U,S,A,

|

|

|

Interesting H-6 on a T-10 ITE Tripod with a small dolly with the

red wheels... Had not seen a small ITE dolly with the red

wheels usually just the larger ones!

|

|

ABOUT THE ITE TRIPOD, HEAD & DOLLY REFERENCE

SECTION AT SMECC

We have merged the contents for scanning purposes of " The Don

Norwood ITE Collection" and "The AVR of Phoenix ITE

Collection" Here at SMECC. The material will al retain its source

of accusation but will be presented in a combined form.

This consists of catalog sheets, catalogs, maint material and data that

has been unseen out there for ages.

Even our previous offering of the skimpy, but yet the only online

reference material was getting quite a bit of traffic.

I remember when I first started trying to get info on ITE stuff when I

was putting that Phillips LDK-20 up so I could use it and roll it around

.... I had a ITE tripod and there was no weight specs etc out there for

what it would handle. How irritating not to be able to find data!

Don was helpful with a copy of a chart that was in some of his

literature so I put it up online and other people started referring to

it also Then thanks to Don Norwood and AVR of Phoenix we acquired a

large collection of catalog sheets and maint. info and have some

articles on company history for ITE and other Tripods and Pedestals.....

If anyone else has an resource material in paper or electronic image

form please let us know ASAP and we will collate it in with the other

material we are currently scanning and placing on the web site.

We have some nice sections on MILLER and SATCHLER and O'CONNOR and

VINTEN coming up to out of the treasures that people have given us. The

other brands will follow after completion of some of the ITE material.

REMEMBER - Looking for any Illust. Parts breakdowns, maint. manuals,

sales lit. oral history form people that worked at the companies etc....

ANYTHING!

Many Thanks Ed Sharpe - Archivist for SMECC 623-435-1522

Please ship paper goods with insurance and tracking to:

COURYHOUSE/SMECC

ATTN: ED SHARPE - ARCHIVIST

5802 W. PALMAIRE AVE

GLENDALE AZ 85301

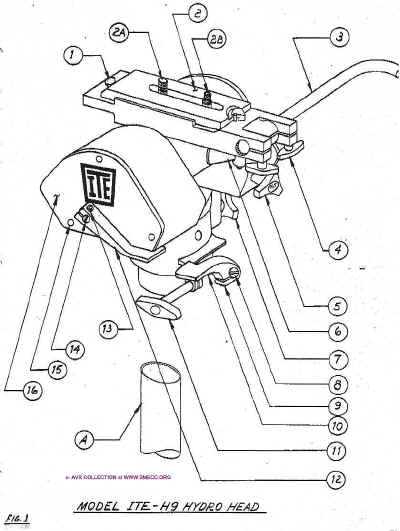

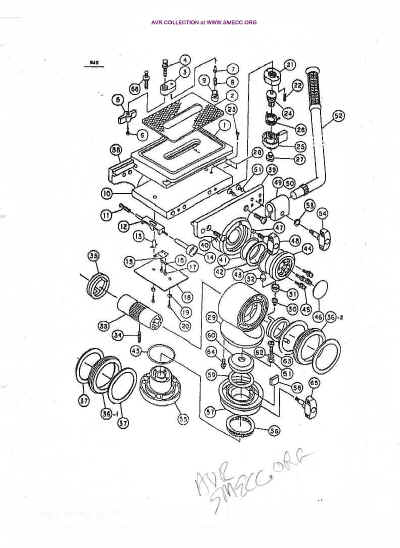

ITE H-9 Hydro Head Data and Maintenance

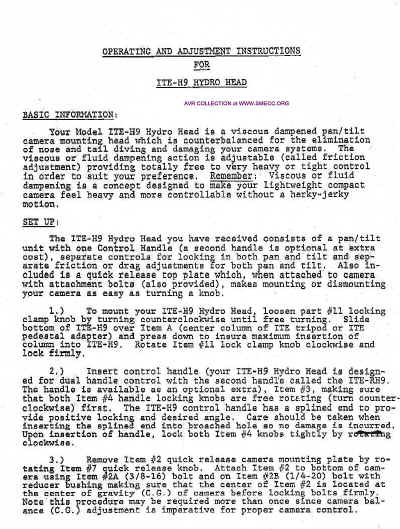

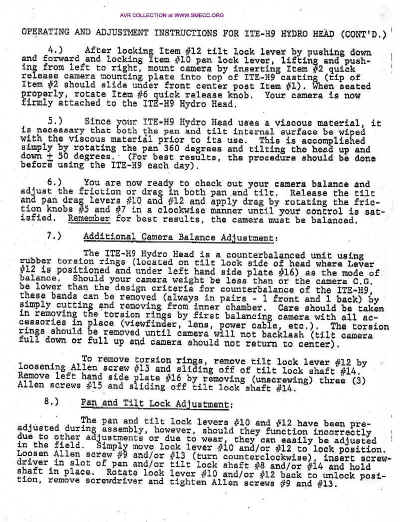

OPERATING AND ADJUSTMENT INSTRUCTIONS FOR ITE-H9 HYPRO HEAD

- BASIC INFORMATION :

Your Model ITE-H9 Hydro Head is a viscous dampened pan/tilt

camera mounting head which is counterbalanced for the elimination

of nose and tail diving and damaging your camera systems. The viscous or fluid dampening action is adjustable (called friction

adjustment) providing totally free to very heavy or tight control in order to suit your preference. Remember;· Viscous or fluid

dampening is a concept designed to make your lightweight compact camera. feel heavy and more controllable without a

jerky motion.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

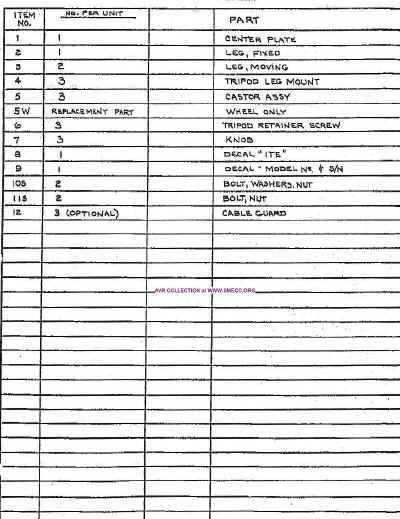

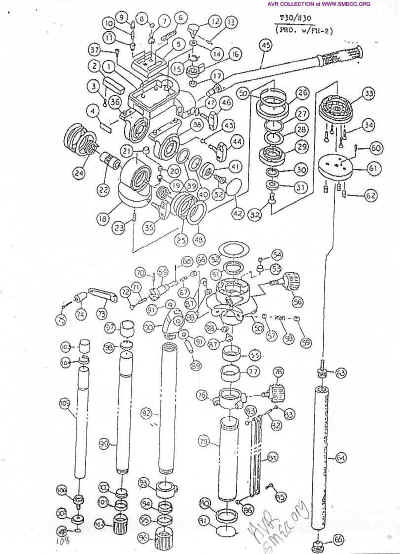

ITE H-30 and T-30 Head and Tripod Data and Maintenance

|

|

|

|

ITE H-40 Head Data and Maintenance

ITE T-40 Tripod Data and Maintenance

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

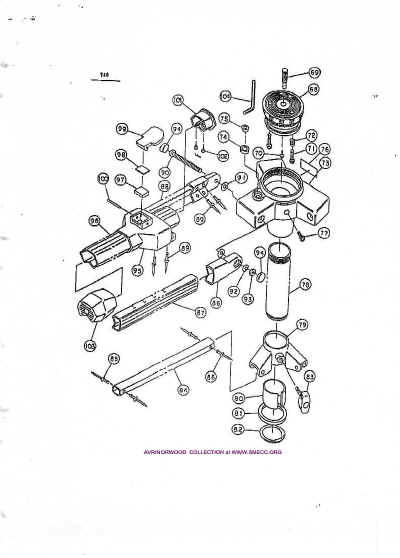

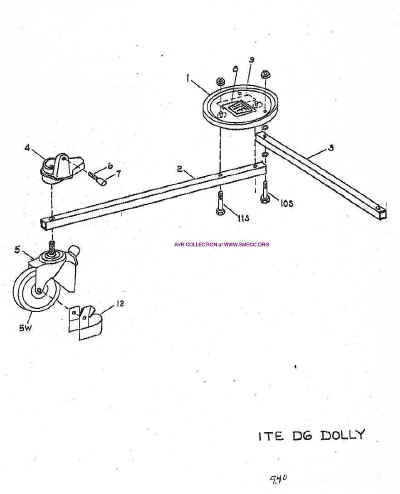

ITE

D6 DOLLY Diagram ITE

D6 DOLLY Diagram  |

The ITE-D8 Dolly

The ITE-D8 Dolly is a heavy-duty system

designed for support of camera loads of

up to 250 pounds. It is a perfect

companion to the ITE Model MT1, T10

and new T14 family of tripods.

This Dolly is of rugged design and

includes 8x1 %-inch durathane-tired

wheels which may be indexed at 450

increments and positively locked at any

position.

The wheel system incorporates a 45-inch

pivot diameter with two-inch, heavy-duty

legs which may be locked into 1200 position

with respect to each other or folded

into a compact package for storing.

ITE Tripods are easily attached to the 08

Dolly by use of a spherical ball socket

and over-center retainer lock screw/knob.

Cable guards are available at no additional

cost, if required.

ITE is a leader in the design and

manufacture of camera heads, dollies,

pedestals and accessories for broadcast,

industrial, educational and closed circuit

television applications. Our products are

in use by stations throughout the world.

The ITE product line has been designed

with your camera in mind. ITE products

provide professional camera support and

control for virtually every video camera

package manufactured. The ITE line is

marketed worldwide by all camera manufacturers

and by leading dealers and

distributors.

|

SPECIFICATIONS

Load Capacity 350 Ibs. (157.50 kg.)

Folded Length 30" (75 cm.)

Folded Width 16" (40 cm.)

Height 14" (35 cm.)

Diameter (wheel pivot) 48" (120 cm.)

Wheel Diameter 8" (20 cm.)

Optional (extra-cost) Accessory:

Low Boy Hi Hat -19" (47.50 cm.) off floor

|

|

|

WEDGE ADAPTOR ASSEMBLIES

The ITE Wedge Plate and Adaptor

combination provide for rapid

attachment and removal of camera

from pan/tilt head.

ITE-ADAPTORS

For interface of all ITE products.

ITE-HH HI-HAT

HANDLES

A wide variety of zoom handles

are available for all ITE tripods.

ITE-H9T47CB CLAW BALL ADAPTOR

Interfaces ITE-H9 Head

to -T4, -T7 and -T12 Tripods.

ITE·CB3 CLAW BALL ASSEMBLY

for -T4, -T7 and -T12 Tripods.

QUICK RELEASE ASSEMBLIES

The ITE Quick Release Assembly

provides for rapid attachment and

removal of camera from pan/tilt

head.

|

|

|