|

Most folks haven't even

heard of a wire recorder..... much less ever seen a steel wire

recorder. Before the development of oxide based magnetic tape,

"glorified" steel piano wire was the dominant media of choice.

The technology of magnetic recording dates back to 1878, when

Oberlin Smith proposed the idea of recording telephone signals onto a

length of steel piano wire. Over the next thirty years the technology

evolved at a "snail's pace"; stalled by lack of adequate and

cost effective electronic amplification. By 1930, advances in electronics

allowed the first commercially successful wire recorders to be introduced

as dictating machines and telephone recorders in Europe and North America.

During WWII, the machines found their way into the BBC who employed banks

of them for sending messages to the French underground. Meanwhile the US

Army & Navy also employed them for similar purposes in their

operations centers. Following the war from 1947 to 1952, wire recorders

became popular in America and across Europe, and started showing up in

many homes. The wire recorder was the very first reliable audio recorder

to find it's way into the American home in significant numbers. In their

"Hay-Day", wire recorders were quite the item !

The advent of oxide based magnetic tape had many benefits over steel

wire.... Mainly the ability to record and playback in stereo. Thus

magnetic tape put an end to the wire recording era.

Signals recorded on steel wire recorders have held up quite well

over the years and the sound quality was fairly good considering the

limited technology of the day.

Depicted above is a Webster 80-1 which sold for around $150 back in

1947. Though early wire recorders used a DC bias which literally

"brute forced" the modulated audio current and subsequent flux

change onto the wire, the Webster's used a 40 kHz bias frequency for

greatly improved fidelity.

1878 - An American mechanical

engineer named Oberlin Smith proposes the idea of recording telephone

signals onto a steel wire. Though it never

went any further than just an idea, the concept of magnetic wire

recording was born.

1898 - Danish inventor

Valdemar Poulsen explores further the principle of magnetic recording.

The machine he developed was called the Telegraphone, and is described

as a device to record telephone messages in the absence of the called

party... in effect, the world's first answering machine.

1911 - Lee DeForest, then

working for the Federal Telegraph Company, is asked to develop an

amplifier to allow the recording of high-speed radio telegraph messages

received on a type of receiver called the tikker. Deforest

uses his Audion tube, invented in 1907, to make the first practical

electronic amplifier.

1918 - German inventor

Curt Stille modifies & improves on the Telegraphone by using

electronic amplification.

1939 - Marvin Camras at

The Armour Research Foundation invents an improved wire recorder. Several

thousand were sold to the American Army and Navy. Following the war,

licenses were sold to dozens of American and European manufacturers to

make wire recorders.

1946-47 - The first Amour

Research Foundation licensed wire recorders that appeared in America.

1947-52 - The consumer hay-day for wire recorders

which were then superceded by magnetic tape.

Audio fidelity of a wire recording is very limited

by today's standards, but still quite acceptable considering the

technology at the time. What's amazing is how well those early

recordings are holding up. Typical wire recorder spools hold

approximately 7200 ft of wire which allows approximately 1 hour of

play/record time.

A Wire Recording may be

transferred to almost any modern format such as a CD, DVD or even audio

cassette, though transfer to a CD is the most popular. Converting the

audio to WAV or MP3 computer files can also be done.

Although the wire

recordings are holding up remarkably well, the main concern in the not too

distant future, will be the ability to locate a still working machine.

This is yet another case where the media will out survive the hardware

upon which to play it.

Up until 1946 or so, wire recorder spool

sizes weren't standardized. Armour®, early Pierce® and GE® machines

used a larger spool size than later to come machines, while some Army/Navy

recorders used even larger reels for the recording of intercepted enemy

transmissions during the War.

Most popular during this early period

was the 3 3/4" diameter Armour reels that were 1 1/4" thick as

depicted in the reel shown on the left. Later, when Armour licensed the

technology to companies such as Webster®, Silvertone® and others, a

smaller reel size was adopted as the new industry standard. The standard

reels measure 2 3/4" in diameter and were approximately 3/4"

thick as shown on the right. Each standard reel could hold up to 7200 ft

of wire, which at a 24 ips recording speed would yield up to an hour of

recorded material. Naturally the newer format machines would not

accommodate the older larger Armour reels. Also, the Armour wires were

recorded at approximately a 50% faster speed than the later to come

Websters. Unfortunately, unlike the Webster wires, the Armour wires were

not made from stainless steel, and corrosion is a common problem.

Though all our machines are of the

newer format, we can still recover these early Armour wires. By means of

a fabricated jig to mount the larger wire spool, playback and recovery

of the wire is possible. The correct speed is obtained in our

restoration software which allows playback of the audio file at the

proper speed. Not what may be considered a glamorous solution

warranting technical accolades of the highest order, but since these

early recorders are virtually extinct and parts are nearly impossible to

find, it's a solution that works extremely well ! Whether it's a

"clever" solution or not, remains a matter of debate....

The only drawback to this

"brilliant" solution, is that the wire bailers on the newer

machines were designed to bail the wire back on a 3/4" thick reel,

and not the 1 1/4" thick Armour spools. The only proper solution

would be a complete re-design of the bailer mechanism, necessitating the

fabrication of custom parts. Not impossible, but there's little

demand for these transfers, so it's yet another project around here that

remains still on the "back burner". As such, we have no viable

(or even clever way that's occurred to me so far) to rewind the wire

back on the original Armour spools (neatly and properly, anyways). Thus

these wires will have to be rewound on a newer size spool. Since the

newer spools hold less wire, most Armour wires may require 2 or 3

spools.

Sometimes in the world of vintage

transfers, one has to improvise !

Most steel wire was of reasonable

quality and had a high chromium content for inhibiting rust. Some wire

sold back then was of lesser quality or was stored in a damp environment

- even stainless steel is not totally rustproof.. Avoid playing any wire

that clearly shows signs of oxidation. The rough oxidized wire surface

will rapidly grind the head groove down.

Light oxidation may be removed by

passing the wire several times over a 3M® "scrunge" pad -

lightly moistened in WD-40. This will remove the lightly oxidized layer

as well as provide lubrication for the transfer. Be sure to make

at least 3 cleaning passes using Pellon® or a lint free cloth to remove

the oxidation and crud as well as any excess WD-40. This will enable the

transfer to be made without destroying the record/playback head.

Though you will be tempted to try this on your working recorder, we

advise getting a "junker" with a bad head to merely serve as

the transport for this endeavor, lest your working recorder gets

"trashed" in the process. Moderate to severely oxidized wires

are often too far gone and you would be well advised not to attempt

playback unless you intend to scrap your precious recorder before

project completion.

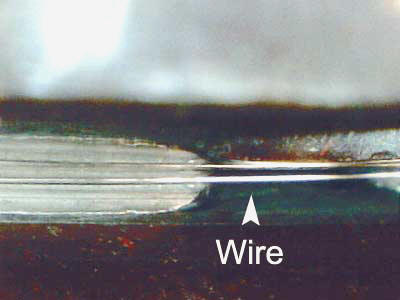

At the right is pictured the

recording head. The dark area to the right is the head gap where the

actual recording/playback takes place. The wire passing over the head

eventually will wear a deep groove in the head guide. The groove can get

so deep that the wire almost disappears and the "canyon" it

managed to carve out over time. The deeper the wear groove, the poorer

the recording quality, as the air gap spacing is critical. Also as a

deep groove is cut, there is a greater chance of a snag and wire

breakage. This head on one of our Webster's depicts very little wear.

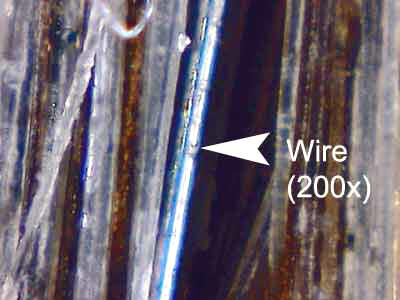

The wire used in all wire recorders is

very thin..... just slightly larger than the diameter of a human hair !

Below to the right, is pictured the wire amongst my gray hairs taken at a

200x magnification. This explains how 7200 feet or so of wire can be made

to fit on a small 2 3/4" diameter reel.

Wire tangles and breakage is a common

problem - especially on old reels not having been played or re-packed in

several decades, where splices tend to snag, or where the head tower

assembly "sticks", resulting in uneven wire packing.

Consequently, some of the snarls can be nothing short of

"hellacious"...... If you enjoy the challenge of solving

complex 3-dimensional puzzles working with hair thin kinky wire, then

untangling a snarled reel will be right up your alley ! Solving a Rubik's

Cube puzzle is child's play compared to the challenge & complexity of

untangling a badly snarled wire. The wire is quite thin and a pain to work

with - especially when having to splice the broken lengths back together.

Though not absolutely necessary, what works great for this are two similar

devices. The first is a fly fishing jig used to tie fly's. The

other is a jig commonly used in electronic assembly work for holding small

components to be soldered or for inspection. Radio Shack® sells a

neat little jig complete with magnifying glass for about $10 or so

(Catalog # 64-2063). On the Radio Shack jig, be sure to pad the alligator

clips with anything soft so the wire doesn't get bent or pinched.

Anyways, both devices will hold the unruly wire and reduce your

frustration levels ! A small pair of tweezers , needle nose pliers or just

nimble fingers are all that's now required to make the splice. A

less glamorous but cheaper solution is to just get some temporary

"sticky dot" labels from an office supply store. Use them to

tape down the unruly wire while you form the splicing knot.

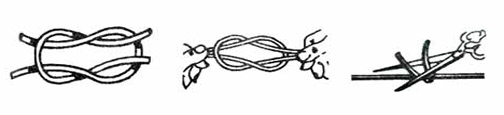

Don't tie just any old knot -

otherwise it will more than likely snag in the head groove and break

again. (a picture of the correct splice follows below).. Worse yet,

is that the broken bits may fall into the electronics, wreaking havoc

& damaging the circuits. After making several splices, you'll develop

a technique and subsequent repairs should take but only a minute or two.

Audio fidelity is poor by modern

standards - There is poor base response with a sharp roll-off below 200

Hz. Hi frequency components are also non existent with very little

response above 5 to 6 KHz or so. Thus wire recordings were fine for

voice recording (typically most energy for the human voice falls in the

200 to 5 KHz range) but offered very limited fidelity for music.

A major contributor to the wire

recording's poor fidelity as compared to magnetic tape, was the poor

quality supplied crystal microphone that all wire recorders seemed to be

cursed with. Microphone technology of the late 40's was pretty crude -

some dynamics, but most were crystal mics, and quality wise, not much of

an improvement over a carbon pile made to vibrate by a stiff diaphragm

- at least for a consumer grade mic anyways. Thus the microphone

itself had poor frequency response suited only for voice reproduction. Mic

sensitivity was also poor and the mic had to be held close to the sound

source for best results. A wire recording made today with a good

quality low impedance microphone actually sounds pretty good and a direct

line level connection even better !....... not hi-fi by any stretch

of the imagination, but MUCH better than the supplied mic.

Another point worth noting, is that very

few of the wire recorders had accurate level meters - or more accurately,

ANY recording level meters. Most had a neon "magic eye" to

supposedly prevent setting too high a recording level. The "magic

eye" was a "somewhere in the ballpark" reference at best.

Most folks paid it no heed or didn't understand it's use anyways, and thus

recording levels tended to be all over the place.... being either

driven into clipping (as in children's screams) or recorded down "in

the mud". Even so, when recorded at anywhere's near the proper levels

with the mic in close proximity to the source, the recordings even after

50 years or more are perfectly intelligible. Compare that to early

magnetic tape...... most early magnetic tapes which by now have ended up

in a landfill due to oxide shedding.

On the plus side, wire recordings suffer

very few of the maladies associated with the degradation of magnetic tape.

Wire doesn't suffer from the fatal effects of hydrolysis, oxide shedding

and binder de-lamination as does magnetic tape. Though the wire is subject

to oxidation, most manufacturers added enough chromium to the steel to

minimize the effects. Like it's tape counterpart, it is subject to

slow erasure by long exposure to stray magnetic fields or repeated play in

a machine that needed demagnetizing. Even so, wire is less effected (note,

I didn't

say UN-affected) by stray fields as compared to magnetic tape however.

Based on our own observations, wire

recordings are already holding up amazingly much better than their

magnetic tape counterparts for the reasons just mentioned. Unlike tape

degradation that ultimately yields magnetic tapes unplayable, wire

recordings' largest enemy is corrosion of the wire due to improper

storage, or the wire having to be discarded after a bad snarl.

Though anything but "Hi-Fi", few will actually require audio

restoration if transferred from a machine maintained in good operating

condition.

Wire Recording Life Span Expectancy

Even though we feel that wire

recordings will last another 50 years or perhaps even longer based on

how they've held up so far, the main consideration here will be trying

to find someone with an old wire recorder still in good operating

condition in another 10 years or so to make the transfer. This is

another one of those cases where the media will outlive the availability

of the equipment on which to play it.

No other magnetic recording media to

date has so far matched or even come close to a wire recording's

longevity. It remains an impressive record that has yet to be

broken.......

Use the following splice - if done

properly, it will not snag.

1. Tie the ends of the wires

together with a square knot.

2. Pull the knot tight.

3. Cut off the loose ends close to

the knot.

This splice will pull through the

groove of the recording head without catching.

It is recommended that 3 foot leaders of #8 sewing

thread be tied to both ends of the wire. The inside leader should be

permanently tied to the supply spool and greatly reduces the possibility

of wire breakage at the ends. A simple square knot is used to secure the

thread to the wire.

Like magnetic tape, avoid storing or

placing wire reels in close proximity to magnetic fields and store them in

a dry environment. Moisture and the subsequent resulting oxidation,

are both the recording wire as well as the recording machine's worst

enemy. Place several packets of silica gel desiccant in the case

before putting the recorder and reels away and store in a dry, temperature

controlled environment. Silica gel is commonly available in most craft

shops and some hardware stores.

Interested in acquiring one ? They often show up

on eBay, though you might have to wait awhile for one in good working

condition to turn up. Note: despite the overly optimistic claims

made of "working just fine", "As New !!!" or

being in "Mint" condition, nearly all are in need of repairs or

general maintenance of some sort. Experience dictates that unless

the seller is willing to give at least some sort of warranty, you're best

advised to "pass" or view it as a repairable or parts machine

only and bid accordingly.

We are often asked if we repair wire

recorders...... Though we perform our own repairs and servicing, our

services are limited to the transfer and recovery of vintage recordings.

For the repair and servicing of wire

recorders, you can contact:

West-Tech

Services: www.west-techservices.com

Most wire recording servicing can be performed yourself.

This is not an extensive dissertation on the repair or maintenance of a

wire recorder, but rather some simple things you can do to prolong it's

life... If you're not comfortable with such

endeavors, then it might be better to have a technician perform the tasks.

Yet, it's actually quite easy to do...... First, above all - UNPLUG

the unit before delving inside. All wire recorders are pretty much of the

same basic design, so the following will apply to almost anything out

there...

Ok, say you "lucked out" and found a working

one. To keep it working, it's going to require a little

TLC.....

Begin by removing the unit from it's case (surprisingly,

this is the most difficult part..... locating the the right screws !). On

most of the Websters, there are 4 brass Phillips head screws on the bottom

and one each on the left & right sides. Once out of the case, the rest

will be easy ! If you have access to an air gun, blow the dust and

years of accumulated crud off the electronic components and tubes. The

dust acts as an insulator and will cause overheating (Vacuum tubes

generate lots of heat !). Also closely inspect for pieces of broken

wire that managed to fall inside...... Small pieces of broken wire can

short out the circuits and result in severe damage depending on where they

land. (which is inevitably where they WILL land to wreak the most damage

for reasons not fully understood).... Again, an air gun works great

for locating and dislodging wire bits, loose screws and other accumulated

"junk".... Cleaning out the inside of some cases,

often more resembles an "archaeological dig" than it does a

simple cleaning. Small pieces of broken wire falling into the mechanism

(usually the result of snarls and sloppy splicing techniques) is a common

problem and the cause for many wire recorder "early

retirements".

Do not touch the glass tubes with your fingers. If you

do, be sure to wipe the oily residue off, as the oils present in your skin

will cause early tube failure !

Wire Snarls

So endemic is this

problem to wire recorders, I've decided to include

a section specifically addressing this topic.

TIPS:

Before even threading any wire for

playback, first insure that the machine is working correctly -

especially the bailer. Place the machine in play (you don't even need a

wire mounted) and note the head/bailer smoothly moving up and down over

it's FULL range. On most machines, the bailer is driven by the take-up

reel and you needn't even have a wire threaded up to check for proper

operation. You can lightly

press down on the head to check for it's full range of travel. It should

not bind or get stuck in ANY position. This simple check for

proper bailer operation will save many many hours of untold grief or

sadly having to discard a badly snarled wire, which is almost always

absolutely guaranteed if the bailer mechanism is not functioning

perfectly. I cannot overstress enough the importance of proper bailer

operation.....

Check take-up reel

tension. It should be within specification. Either a tensiometer

or torque gauge is required for this, and is best done by a service

technician who has such an instrument and is familiar with wire

recorders. Too much or too little tension or back-tension on the

take-up reel, will result in upper wraps being literally pulled under

lower wraps - even with a properly operating bailer. Without a

tensiometer or torque gauge, setting the proper back tension is

impossible, but here is some "rules of thumb" . As the

reel rotates, the tension should not vary. Also the proper tension is

just that amount that ensures proper packing of the reel without having

loosely wrapped wire. The proper wire tension is maintained

basically by a clutch allowing controlled slippage. Most machines use a

felt pad for the clutch which often becomes glazed with crud over the

years. The felt pad can often be reclaimed by lightly abrading off the

glaze with some medium grit sand paper. Most Websters have a spring type

of adjustment that allows setting the proper pressure applied to the

felt clutch pad.

If a wire snarls on

playback, stop playback immediately and deal with the tangle before

matters become much worse - as they most assuredly will.

NEVER try and brute force

out a snarl by pulling and "hoping for the best". It rarely

works and almost always results in your pulling upper wraps under

overlying ones, or cinching the snag even tighter, making what started

off as a simple problem, now a much more involved one. Trying to tug out

a snarl will almost always kink the wire and the kink will then have to

be cut out - though sometimes a loose kink can be carefully unbent and

run between your fingers to smooth it out if not kinked too tight. (Be

sure to wear white gloves or remove skin acids and oils from the wire

after doing this).

If you are forced to wind

a wire by hand (not recommended), make certain it is tightly packed

throughout. Loosely packed wires will immediately snarl on playback, and

days of effort may all be for naught.

Many

if not most wire snarls are machine induced. A properly maintained wire

recorder will rarely if ever, snarl a wire that is not corroded,

previously kinked or too loosely packed to begin with. Almost all wire

recorders use a cam assembly for raising and lowering the head tower

(called bailing) thus distributing the wire evenly on the take-up or

supply spools. The head tower bailer assembly is usually driven by the

take-up reel drive mechanism. In just about all machines, the head tower

is "powered" up by the cam, but gravity is the sole mechanism

that allows the head to lower thus following the cam, as the small

diameter of the cam rotates into position. After 45

years or so, the unit is in dire need of lubrication - you can absolutely

count on it ! The first to jam due to dried grease is the all important

head bailer. The head/bailer slides up and down in a guide and must be

lightly greased, as well as the worm gearing and cam assembly.

Before applying new grease, the old dry grease must first be removed. Use

"PB Blaster", which is a penetrating solvent available at

any half decent auto parts store. Spray some on a Q-tip and have at it

(NEVER spray directly in the mechanism) ..... Re-lube with a light

lithium based grease. A drop of machine oil (or even motor oil if you

don't have machine oil) on both ends of the motor shaft should also be

done. Many

if not most wire snarls are machine induced. A properly maintained wire

recorder will rarely if ever, snarl a wire that is not corroded,

previously kinked or too loosely packed to begin with. Almost all wire

recorders use a cam assembly for raising and lowering the head tower

(called bailing) thus distributing the wire evenly on the take-up or

supply spools. The head tower bailer assembly is usually driven by the

take-up reel drive mechanism. In just about all machines, the head tower

is "powered" up by the cam, but gravity is the sole mechanism

that allows the head to lower thus following the cam, as the small

diameter of the cam rotates into position. After 45

years or so, the unit is in dire need of lubrication - you can absolutely

count on it ! The first to jam due to dried grease is the all important

head bailer. The head/bailer slides up and down in a guide and must be

lightly greased, as well as the worm gearing and cam assembly.

Before applying new grease, the old dry grease must first be removed. Use

"PB Blaster", which is a penetrating solvent available at

any half decent auto parts store. Spray some on a Q-tip and have at it

(NEVER spray directly in the mechanism) ..... Re-lube with a light

lithium based grease. A drop of machine oil (or even motor oil if you

don't have machine oil) on both ends of the motor shaft should also be

done.

As stated before. dried

grease or lack of lubrication is a common problem that results in the head

tower not falling freely, causing the wire to be packed wrap upon wrap

atop of one another. The uneven packing due to the failed bailer, results

in upper wraps being pulled under lower wraps - especially if the wire

tension is not within specification due to grime on the clutch assembly,

corrosion on the supply shaft or a glazed felt clutch pad. When this

happens, there will be hundreds of snarls created - - the end result being

that the wire will have to be discarded and not worth the effort to try

and untangle and splice back together. For those brave folks with LO TS

of spare time on t TS

of spare time on t heir

hands or where the tangled wire is priceless and must be recovered at ANY

cost, here is the procedure....... heir

hands or where the tangled wire is priceless and must be recovered at ANY

cost, here is the procedure.......

Beware that attempting to

untangle such messes will likely involve literally 100's of hours on some

tangles. Begin by cutting out the kinks, and splicing the undamaged

sections back together. Don't worry that some spliced sections may

be out of order if the tangles are numerous and you can't follow the

sequence..... Get it untangled and spliced back together first to

make the transfer. The out of sequence sections are best put back in their

proper order by audio editing software rather than messing around more

with the unruly wire. Tools required for this frustrating endeavor are a

pair of sharp scissors, a common pin for following/tracing the nightmares,

tiny needle nose pliers, magnifying glasses , Scotch Tape or orange label

dots for temporarily securing segments, several bottles of Tylenol

and optionally (though highly recommended), a LARGE bottle of rum.......

(for medicinal purposes only). Kinks that have formed loops must be

cut out - do NOT attempt to splice together segments containing kinks or

another unbelievable snarl worse than the current one (if you can even

begin to possibly imagine it) will soon ensue.

Take-Up Reel Snarls:

Should the wire get snarled on the take- up reel, avoid at all costs the

temptation to remove the screws holding the top cover to free the snarl -

BIG MISTAKE !!! ..... Once "sprung" free, the resulting

tangle will almost always result in the wire having to be discarded, or

literally 100's of hours spent untangling the unbelievable mess..

Take-up reel snarls are ALMOST ALWAYS caused by a faulty bailer, improper

back tension or the wire being too loosely packed sometime back in the

wires' deep past.

Supply Reels Snarls: Luckily,

there is no cover to remove on the supply reel so the potential of making

matters much worse is eliminated. The best procedure to use on a snarled

reel, is to first cut the wire with a pair of scissors, then push the

bitter (cut) end to reveal the loop, and pull the bitter (cut) end through

from under the overlying wraps. A sewing needle will come in handy for

probing and freeing any kink. Again, never tug a snarl, or it will

cinch up tight and make tracing it much more difficult. After

untangling 6 feet or so, splice that section back on the take-up reel.

When hand wrapping wire on the take-up reel, make sure it is packed

tightly, as loose wraps are almost guaranteed to snarl again. Once

free, wind slowly by hand for about 10 feet or so to make certain there is

not a second snag close by, as is often the case.

Sadly, there is no magic trick to

removing bad snarls other that the tips related above. The procedure is

time consuming and often frustrating (unless you enjoy the challenge of

solving 3 dimensional puzzles such as a Rubik's Cube). Some or many

sections of badly kinked wire will unfortunately be unsalvageable. Keeping

the machine well maintained in addition to having the recording

transferred to an audio CD, is strongly advised. Even after having the

wire recording transferred, please hold on to and preserve the original

wire recording - even if it's still a snarled mess. Some unwitting soul in

the future or someone who just lives solely for the thrill of self abuse,

may take on the challenge !

Unlike magnetic tape, wire recordings

are holding up much better over the decades than their magnetic tape

counterparts. Please preserve the original recording...... As much of the

original material as possible should be preserved on that medium for the

future.

Wire Recorder Fast Forward Function ?

None of the wire recorders produced by any of the

manufacturers have a fast forward function to allow a quick preview

of the reel contents. It was not an important feature that was left

out by any of the manufacturers by simple oversight or for economic

reasons to keep prices low (even their top of the line machines did not

have a fast forward), but rather to avoid fast shuttling of any wire

coming off the small spool. The steel wire wants to stay

"coiled" and any wire pinching needs a millisecond or so to pull

itself out "gracefully" without snarling. Thus the high

resulting rpm of the supply reel in a fast forward, would result in

many a snarl, and thus the reason why none of the wire recorders had a

fast forward function.

To get around the problem on high speed rewind, you'll

note that all wire recorders regardless of make or model, have a much

larger take-up reel..... It's not a coincidence ! The over-sized

take-up reel upon which the wire is now being supplied on a rewind,

rotates much slower. Even with a large take-up reel, most wire

recorders by design aren't "blazingly" fast on a

"high" speed rewind, as they all average between 6 to 8 minutes

to rewind a full spool. Some of the early Pierce's used the same size

reels for both the supply as well as the take-up, but those machines

didn't have what could even remotely be considered a high speed rewind.

Now you know !

Dirt & grime inevitably will accumulate in the head

groove, causing the wire to "stick", resulting in a wow or

"spotty" playback. The head groove can be cleaned with Xylol

(available at almost any hardware store in the paint section). Use a

folded cloth or a small stiff tooth brush soaked in the mentioned solvent

to remove the sticky grime. Be careful just to clean the groove and not go

deeply into the head gap, otherwise potential damage to the head windings

may result. Isopropyl Alcohol can also be used to clean the brake pads and

idler wheels. Use only 99% pure medical grade IPA, as the standard off the

shelf supermarket variety contains only 60% - the remaining 40% being

mostly water. Note that Xylol should not be used on any rubber parts or

felt pads, as it is an extremely effective solvent that will not only

quickly dissolve the grime, but will also dissolve the rubber parts, as

well as the adhesive holding the felt pads in place.

Over a period of time, the mechanism will become

magnetized, which is a normally occurring process. Thus, every 10 hours of

use or so, the unit should be demagnetized for the best fidelity. This

includes the heads as well as any metal surfaces which the wire comes in

contact or in close proximity to. If not demagnetized, any wire

being played will be slowly erased by the magnetic field of the surface

over which it passes. Also, audio fidelity will suffer and noise levels

will increase should the head become magnetized.

If your demagnetizer is equipped with an on/off switch,

be sure to turn it on before bringing the probes close to the surface to

be demagnetized. Keep the power on while demagnetizing, and then SLOWLY

pull the probes away from the machine before switching it off. Avoid

turning the demagnetizer on or off when the probes are close, as the

sudden power surge and resulting spike of magnetic flux generated will

actually magnetize anything in close proximity. Thus with the

demagnetizer power on, SLOWLY bring the probes close to the surface and

then SLOWLY pull the probes away before turning off the power. Avoid

contacting the surface to be demagnetized..... Bring the probes

close, but avoid direct contact !

Demagnetizers can be purchased at your local Radio Shack®

or any half decent electronic supply. Look for the type with two probes to

get into tight places. A handheld bulk type demagnetizer can be used

on larger areas such as the take-up reel.

Electronics

Though far from an in depth

discussion or service manual type dissertation, here are some tips as

applicable to the vacuum tube electronics....

(Note: Vacuum tubes are

referred to as "Valves" in the United Kingdom) - though

techs sometimes refer to them as "Glow Bottles" or "Ether

State Devices"

Vacuum tubes operate at

much higher and potentially lethal voltages than those encountered in

transistor circuits. Unless you are experienced in troubleshooting such

devices, it is strongly suggested you leave such endeavors up to a trained

technician familiar with vacuum tube circuits. (Note: These techs are

usually easy to spot, owing to their grey or white hair.)

Wire recorders have the

simplest of electronics....... A simple filtered unregulated bulk

power supply, playback & recording amps (shared) as well as a bias

frequency r-c oscillator circuit. There's not much to them. Despite

their simplicity, the electronics have two inherent weaknesses.....

the vacuum tubes and the capacitors.

The Webster Model 180 for example, used a

6X5 full wave rectifier tube - 6SN7 twin triode output amplifier operating

in a "push/Pull" configuration - 2 - 6SC7's twin triode

Pre-amplifiers - and a 6V6 pentode beam power tube for the bias

oscillator.

Replacement tubes are available from many sources on the

net and are almost to be considered normal maintenance items owing to

their limited life span as compared to transistors. You can even special

order most of them through your local Radio Shack® store.

Thirty years past or so, most electronic stores (Radio Shack's & even

the local drugstore) had tube testers on their premises - most of which

you could use yourself. Today, those testers are all but gone with the

advent of the silicon transistor and integrated circuits. So how do you

identify a bad tube without a tube tester ? Sadly, other than the

obvious physical damage, you don't. Luckily, most wire recorders had only

5 tubes, and without a tester or an oscilloscope, you will simply have to

"shotgun" them all.

Aside from the tubes, an all too common electronic

problem are the old dried out wax/paper capacitors. They are notorious for

failing, and should the power supply rectifier caps start to go, you'll

get a nice LOUD 60 cycle hum and probably not much else. For less than $20

and several hours of scrounging around for parts, substitutions and

soldering, just replace all of them while you're at it. When substituting

capacitors, make certain the working voltage is either the same or greater

than the original - NEVER less. If replacing with electrolytic's, be

certain to observe proper polarity.

A slight hum with low audio output is also a sign of a

partially failed power supply filter capacitor. The B+ plate voltage

(the output out of the 6X5 in the case of the Webster 180) must be clean

dc voltage, lest nothing will work right.

Another thing to check that frequently causes problems,

is the two section record/play switch. The wipers often become "crudded

up" and may require cleaning (TV tuner cleaner works best -

also available at your local Radio Shack). Also check for broken wipers

that sometimes break or make poor contact due to metal fatigue after many

years of use. Since the wire recorder electronics shares almost all the

amplifiers for the playback as well as the record functions, a simple

broken/dirty selector switch (depending on which pole is faulty) can often

render the entire unit non functional.

A little TLC is all that's really needed to keep these

great old machines running. They were built like tanks and almost

everything was "over-killed" - all they often need is a little

cleaning and some lubrication.

So how does a vintage audio wire

recording actually sound you ask ?..... This clip is typical of a wire

recording in just average condition. These MP3's are raw captures

and no restoration has been applied.

The recording is an historical excerpt from a commentary

criticizing President Truman and the Wage Stabilization Board.

April, 1952 - (Amazing what will turn up on some of these

old wire reels !)

Short 10 second Clip :

File size: 157K Click

Here to Listen....... 1

Repairing and maintaining vintage

equipment isn't everyone's "cup of tea" however.

For professional quality transfers

to CD, MD, Tape or other formats, just give us a call.

Last Modified: Sept 8,

2004

Copyright © 2003, 2004

Video Interchange

92 George Luce Rd

Waldoboro, ME - Maine 04572

207-832-5064

Northeast Region - New

England

http://www.videointerchange.com/ |