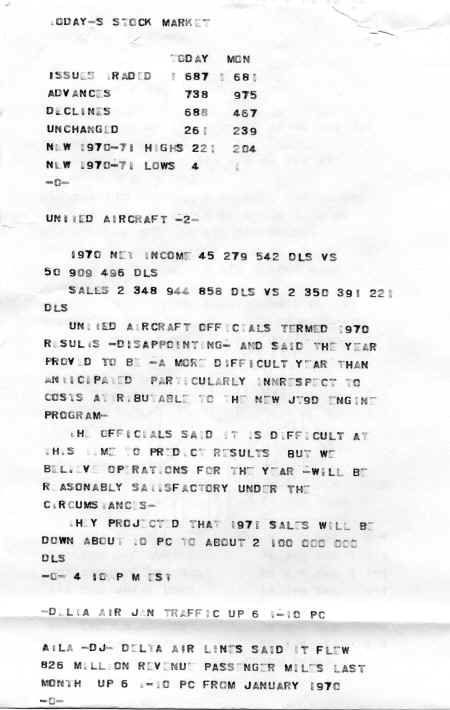

|

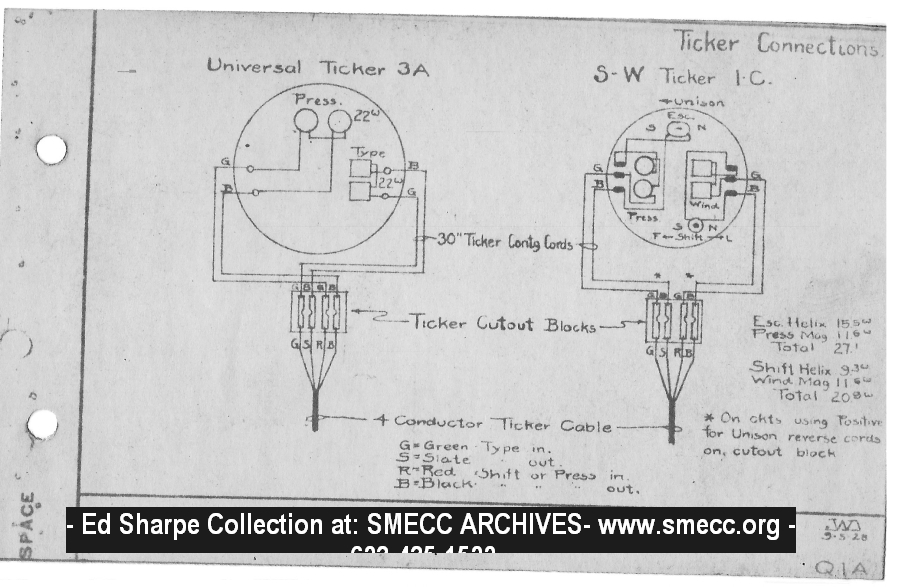

Western Union 3-A : By Douglas A.

Kerr

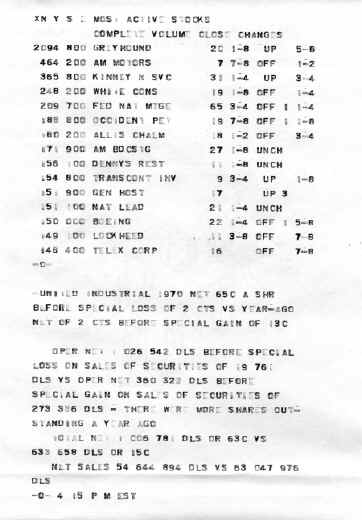

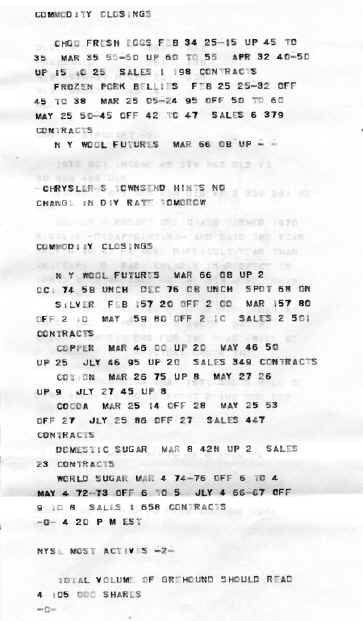

For many years stock tickers of the "Edison" genre (such

as the Western Union 3-A) were used for stock and commodity

quotations, sporting event result reporting (this it turns out being

of most interest to bookmakers), and similar services.

As teletypewriter-based tickers (such as the infamous Western Union

5-A, the "Black Box". made by Teletype Corporation), came

into use, Edison-style tickers retired from stock quotation service

were used to expand inexpensive sporting event reporting services.

The Western Union 3-A that I used to own, and which we will discuss

here, had at the end of its life been in the latter service. I

acquired it from a technician at a Western Union teletypewriter repair

shop in exchange for a box of donuts from the donut shop just down the

street.

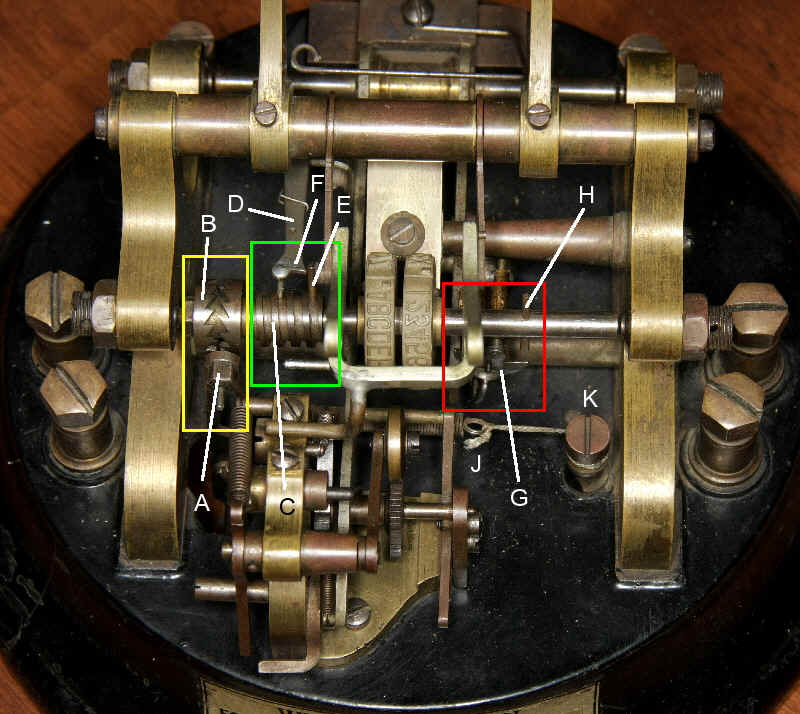

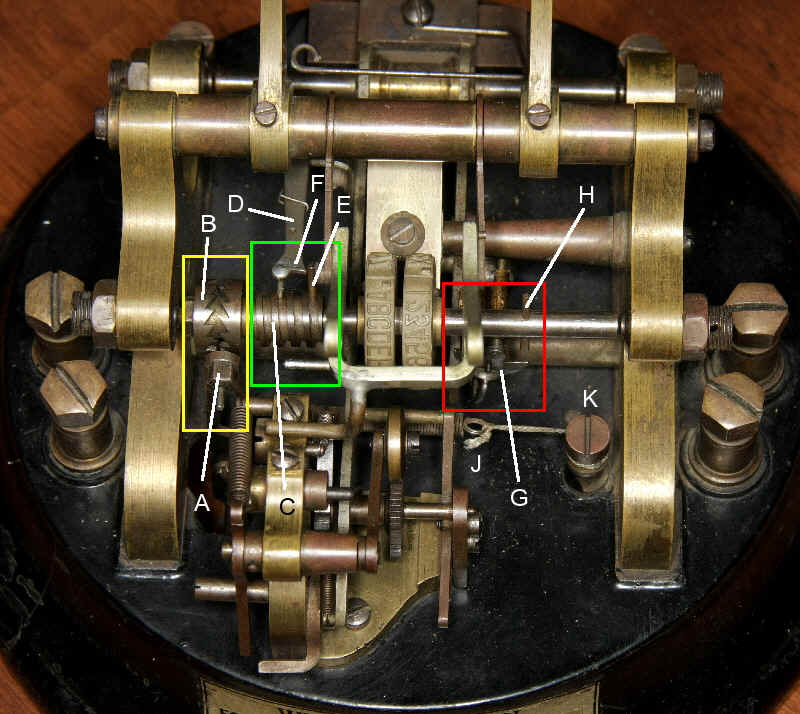

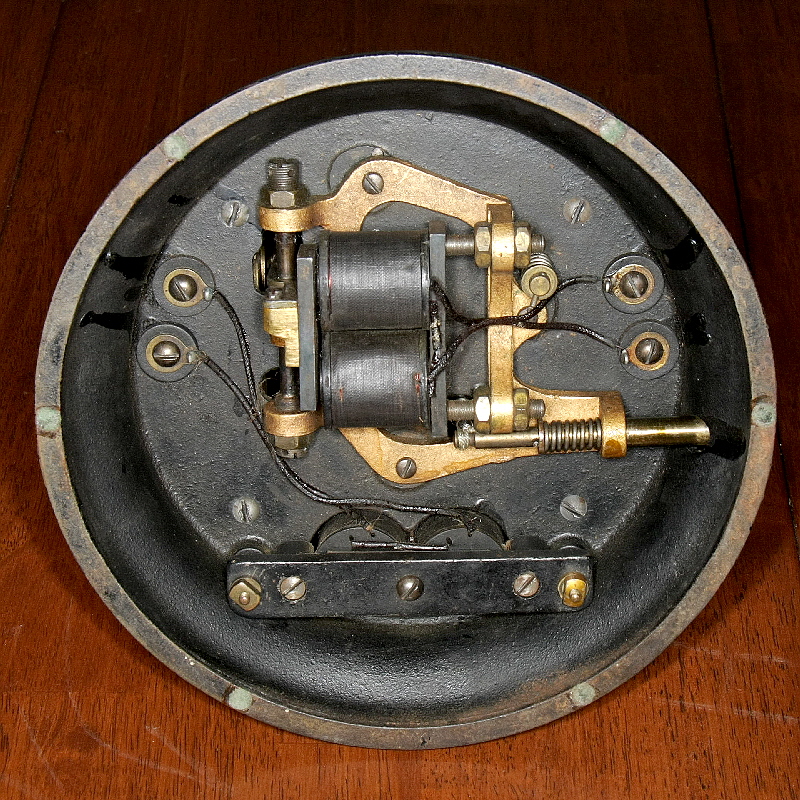

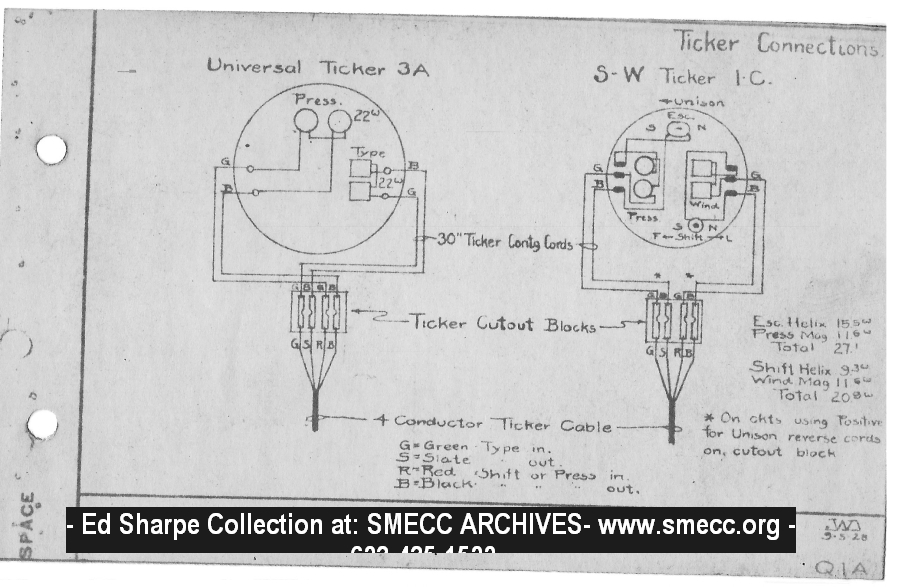

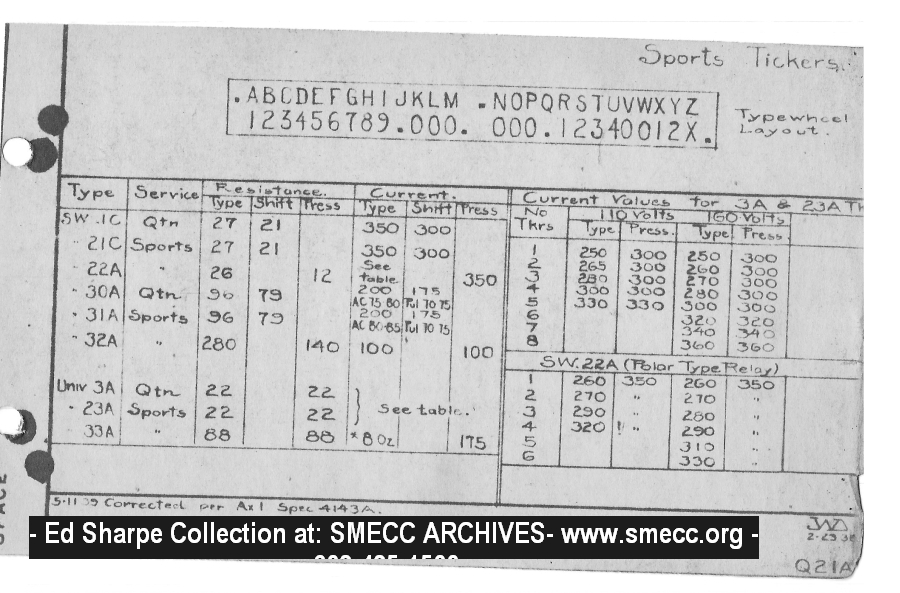

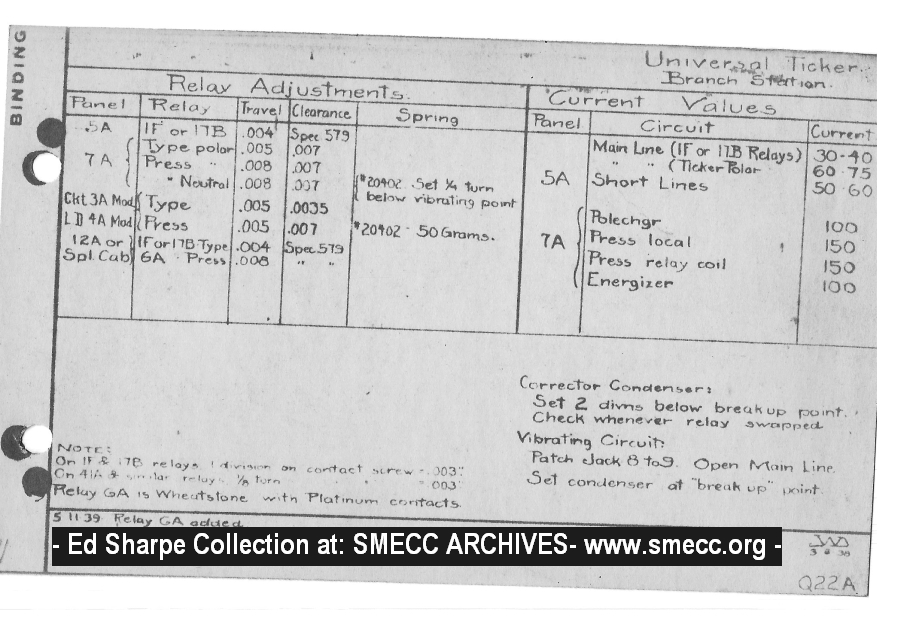

This figure shows the mechanisms of interest:

Photo by: Douglas A. Kerr

The 3-A ticker runs from two neutral telegraph loops (I don't know the

current). Simplistically, one loop carries a train of pulses that

operate a magnet that steps the typewheel to the proper position, at

which time those pulses stop and a long pulse on the second loop

operates a magnet that prints the character, then the pulses on the

first loop resume to move the typewheel to the position for the next

character, and so forth.

We see the binding posts for connection of the two loops on the sides

of the base.

(Another ticker genre uses only a single loop. I'll talk about it

later.)

Both magnets in the 3A are under the base. The "stepping

magnet" operates Arm A. A hardened pin on it moves back and forth

between the tool toothed wheels B. Every transition from operated to

non-operated and vice-versa advances the toothed wheels by one

step. The toothed wheels are on a shaft the carries the type wheels.

The bias spring for the stepping magnet is in fact on the top of the

base, operating on lever A. We see its other end at J. A cord runs

from that end to capstan K, which can be turned to change the bias to

get symmetrical operation of the stepping magnet.

The "hammer" for the printing is in fact a wheel (I will

call it the print wheel) and is under the typewheels. We do not see it

nor the mechanism by which the "printing" magnet moves it

up, pressing the tape against one typewheel or the other (the hammer

wheel is only as thick as one character.) Thus the system uses the

familiar "letters-figures shift" scheme.

Four positions in the character sequence are the LTRS anf FIGS

characters (each one appearing twice). Item G (looks like a manta ray)

is a rocker than moves the print wheel laterally. There are two pins

on the typewheel shaft (H is one of them) that, when in the proper

position, strike one "wingtip" or the other of the rocker,

thus shifting the print wheel to the desired position.

Of course the whole operation of this kind of ticker is predicated on

the position of the typewheels at all the receiving tickers being in

synchronism with a wheel at the sending end that is used to determine

when the typewheels are in the proper position for the character to be

printed.

Of course once the system gets started, and if there are no

disruptions to the loop signal, this will just work fine. But at the

very least, when a new station is introduced into the loop, it needs

to figure out just where we are in the stepping sequence. And indeed,

every so often, it would be a good ideal to reset synchronism in case

there had been some disruption to the stepping loop. This is the task

of the infamous unison mechanism.

On the 3-A, the heart of the unison mechanism is drum C, mounted on

the typewheel shaft, which has a helical groove. A pin at the end of

lever D (and lever D is held downward by a light spring) rides in the

helical groove, and works its way to the right as stepping proceeds.

However, in normal operation, the lever never reaches its right-most

travel limit. That's because each time the the print magnet is

energized to print a character, lever D is lifted out of the drum and

a spring pulls it back to the leftmost end of its possible travel.

But suppose no print pulses are sent for quite a while, Then, lever D

continues to the right, When it gets far enough to the right, its

corner F gets in the way of the travel of the tip of pin E, which

extends from the typewheel shaft. This collision stops the rotation of

the typewheel shaft at what we will call the "starting

position". Of course, the stepping magnet through arm A tries to

keep it rotating, but is frustrated by the collision in the unison

mechanism..

The very same thing happens to the timing wheel at the sending end,

and it is halted at the "starting" position.

Thus to attain or regain synchonism, all that is necessary is to

continue sending pulses on the stepping loop but not any on the

printing loop for a while. After enough time had elapsed for all

receivers to reach the "start" position, a pulse is sent on

the print loop. This "prints" the character at the

"start position, but that turns out to be LTRS, so nothing

prints, and the machine is shifted to "letters case",

another valuable initialization. But the operation of the print

magnet, as always, lifts arm D, which in this case clears the

collision, allowing the typewheel shaft to begin moving again.

So when does this happen?

Well, if traffic is light, it happens any time there is a break in the

traffic. If traffic is not light, the operator nevertheless

"periodically" (and I have no idea what time intervals were

typically adopted) stops sending long enough for the unison operation

to play out at all stations (regardless of their state of synchronism

or the lack thereof).

Single loop tickers

Tickers such as the 3-A require two loops for operation, thus

incurring a substantial facility cost. To avert this, another kind of

ticker uses only one loop (albeit with a small penalty in operating

rate). The loop operates on a polar basis; that is, its two states

both have current but of opposite polarities.

In these tickers, the single loop passes in series through both

electromagnets. The "stepping" electromagnet is polarity

sensitive (it having a permanent magnet as part of its construction to

that end). It moves one way for one loop current polarity and the

other way for the other polarity.

The printing magnet responds to the absolute value of the average of

the loop current over perhaps a several hundred millisecond time

window. So it would not respond to the rapid reversals of loop

polarity that convey the stepping signal, but if that were to stop,

regardless of in which polarity, it will respond after a little while.

So the operation was like this. Polarity reversals on the loop moved

the stepping magnet back and forth, operating a mechanism essentially

identical to what see as items A and B in the 3-Auntil it was (assumed

to be) in the right position for the character to be printed. Then,

just as in the two-loop ticker, this train of pulses stopped. But now

there was no pulse on a second loop. Rather, in due time, the printing

magnet response to the now constant loop current (of whichever

polarity).

A disadvantage was that the relatively long time required for the

printing magnet to realize that it was expected to operate slightly

slowed the overall system throughput.

The tape format

Almost certainly the notion of moving the printing "hammer",

rather than for example the type wheels to shift to the

"figures" characters, as initially done because it was

easier. But (and I can visualize trials of an "improved"

machine that would print characters from both sets in a straight line)

it was realized that the tape format resulting from the shifting

hammer - for a stock quotation system, the stock symbol, always

letters, would print in the lower position on the tape and the price

in the upper position - was found to be very advantageous from

an ease of reading standpoint. (So if an "improved"

arrangement was tested, it probably got a bad reception.)

Thus this "expedient" was kept, and in fact, in two

generations of later tickers, the same format was retained (in some

cases, the mechanism had to go rather out of its way to do that).

And, as the author of the recently-referenced paper on the 5-A ticker

points out, in modern quotation systems, using electronic displays,

the same format convention is followed.

************

ADDED PHOTOS AND INFO-

Photo by: Douglas A. Kerr

Three quarter front view. I never had an ink roller or an ink transfer

roller. I originally had the paper supply reel, but during an unpacking or

repacking or whatever it went astray, which cost me about $1000.00 when I

sold it!

People ask about the glass dome which we always see on this general kind

to ticker in the movies. This model did not in fact have a glass dome as

part of the basic product. There were accessory stands for the machine

available, and some of those had glass domes as part of them.

Photo by: Douglas A. Kerr

Three-quarter rear view. We see the printing electromagnet protruding

through the base at the rear, with it armature on top. The shaft

protruding though the base (has a slot in it) adjusts the bias spring for

the printing electromagnet.

The little wire bail on the printing magnet armature igives a little yank

to the paper tape on each printing cycle so it does not "fight"

the feedwheel.

Photo by: Douglas A. Kerr

Three-quarter front view from above. We can nicely see the stepping and

unison mechanisms, as well as the printing armature. The unison arm is

actually mounted on the printing magnet armature, that being the way it is

lifted out of the helical drum whenever the printing magnet operates to

(to "reset" its "countdown"). It is mounted with a

spring so that when the magnet lets it down it is not jammed into the

helical drum if it doesn't at the moment line up with the helical groove.

It will of course drop in as the drum rotates when stepping resumes.

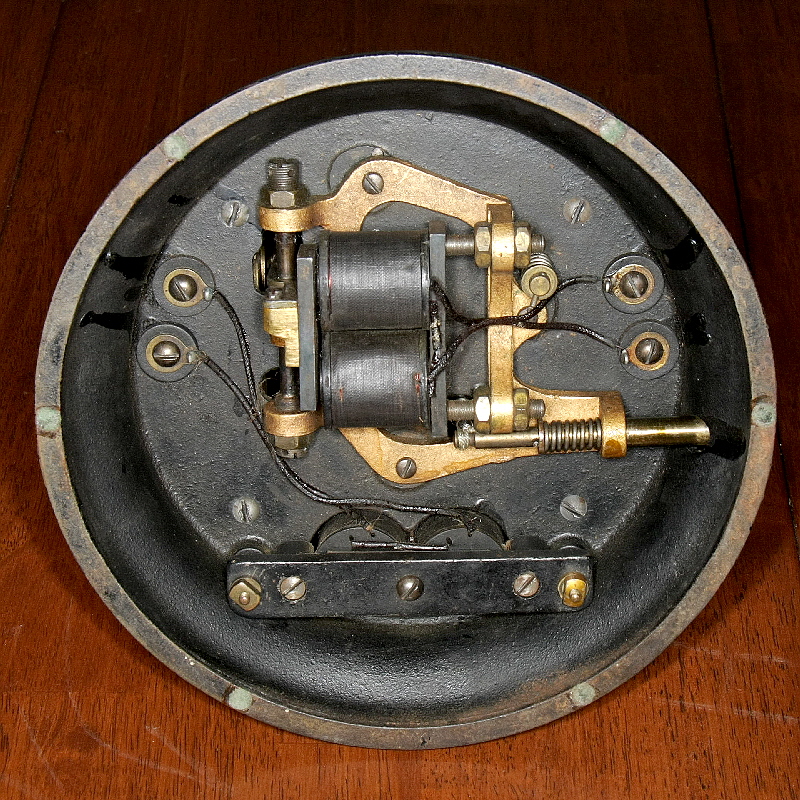

Photo by: Douglas A. Kerr

This is the closeup of the mechanism without the annotation.

Photo by: Douglas A. Kerr

View from beneath. At the top of the picture is the stepping

electromagnet, its armature to the left. At the bottom is the lower end of

the printing electromagnet.

Interestingly enough the shaft that adjusts the bias on the printing

magnet (yes, it too winds up a little cord) is supported by an ear on the

stepping magnet bracket. (We see it protruding through the base at about

3:00 o'clock on this picture.)

|

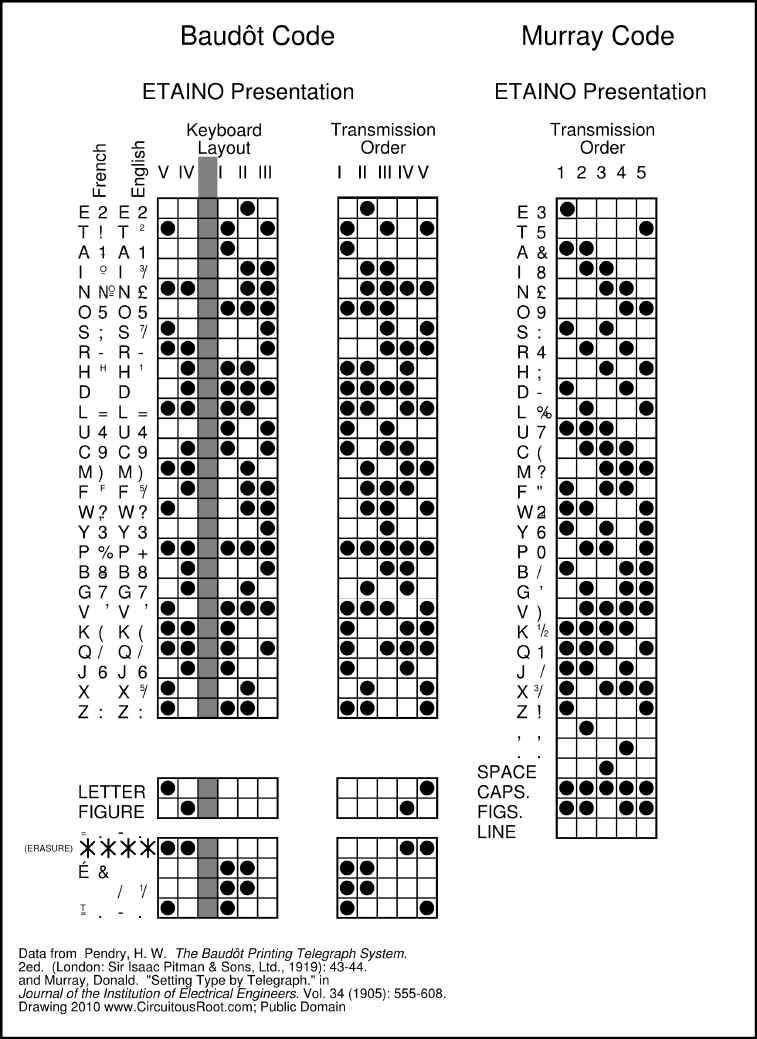

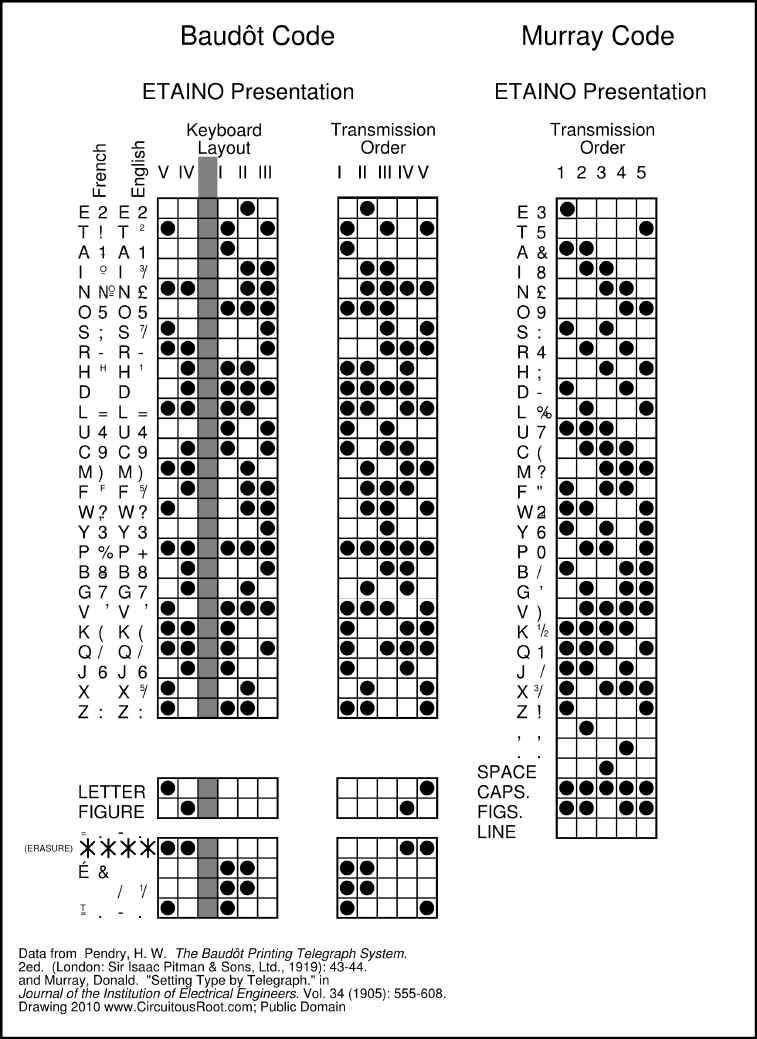

Doug Kerr states : "I remember now, a closely related way of

presenting a telegraph code is called the "ETAINO" presentation

because of its letter order for the Murray code. I had run into references

to that before.

By the way, that turns out to be roughly in order of letter frequency in

journalistic American English (although that is most often cited as "ETAOIN").

I had never until recently known of that relationship, tortured though it

be, for the Murray code.

There is in fact a reference to that in this piece:

http://www.circuitousroot.com/artifice/telegraphy/tty/codes/

Here is a table from that article showing Baudot and Murray codes in

ETAINO order:

Public Domain image from http://www.circuitousroot.com/artifice/telegraphy/tty/codes/

And this is a passage from that article:

Murray says of his code, relative to Baudôt's, that "The only

difference is in the allotment of the letters to the various

permutations, the Murray arrangement being designed to punch as few

holes as possible in the tape." (Murray, 1905, p. 567 (PDF 602)).

Again, I had not known of that criterion.

I note there his use (mathematically questionable) of

"permutation", so I guess it got an early start."

"Model 37 stock ticker." - By David Kerr

There were always a lot of curious "electropolical" matters

affecting Teletype corporation by virtue of its ownership by the Bell

Telephone System.

Many of these flowed from provisions of the 1956 consent decree that ended

the first major antitrust suit against AT&T.

One of particular interest to us was that Teletype Corporation would not

be allowed to sell to its customers outside the Bell System any products

that were not essentially the same ("of a kind" was the term of

art used) as products sold to the Bell System. (This did not apply to

sales to the US government.)

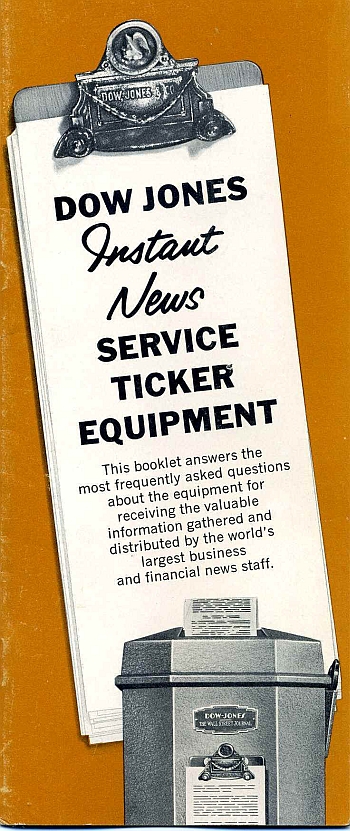

In about 1964, Teletype introduced a new stock ticker, capable of

operating at 150 words/minute, and thus often called the "900"

ticker ( its speed was 900 char/min). It drew upon many design

concepts of the then-emerging Model 37 teletypewriter line, notably

including the use of an "aggregate motion" mechanism to position

the type cylinder (very similar in concept and design the the aggregate

motion mechanism used to position the typebox in the model 37 page printer

(YP). So there was no doubt but that this was the "Model 37 stock

ticker."

We see it here in New York Stock Exchange livery:

But the suits were very itchy about this. No stock ticker service was

offered by the Bell System and thus they would not be a customer for any

such thing (although it was argued that it was "of a kind" with

what might emerge as the Model 37 tape printer). There was concern that a

legal "flap" over the new product would ensue.

In any case, the printer of the "900" was given the apparatus

code "LST", which would mean "model 28 (or maybe 35) stock

ticker" (and there had of course previously been no such thing),

rather than "YST". Evidently the thought was that this way it

would not be so easily seen in the long lists of "L" units, the

list of M37 ("Y") units being pretty small at the time (in fact

at first this was the only one), and tip snoopers to its emergence.

Burry bulletin printer

BOSTON STOCK TICKERS.

http://www.archive.org/details/electricalworld43newy

VOLUME XLIII

-The announcement is made that

the Commercial-Financial Press Association has acquired the Boston

Financial News and the New England stock quotation service, and

through association with the New York News Bureau has become

Boston correspondent for that association. By reason of the changes,

on and after January 1 the service of the Boston Financial News will

be conducted directly by the Commercial-Financial Press Association,

the absolute control of which is in the hands of an interest closely

allied with the New York News Bureau. The new management will

install within the next two or three months an electric delivery service

by means of the Burry bulletin printer, which has for some years

been successfully operated in New York. The publication offices

of the new association are at 35 Congress Street, and the business

offices at 22 Congress Street. Charles B. Strecker is president and

general manager of the company.

https://www.google.com/patents/US839492

Original Assignee, Charles B Strecker

---------

http://www.archive.org/details/electricalworld43newy

VOLUME XLIII

more fun

from there....

.

Rapid-Type Printing Telegraph.—A note on an apparatus of Siemens

and Halske based on the following principle : A disc, near the

periphery of which the letters of the alphabet, figures, etc., are cut

out, rotates at a speed of 2,000 r.p.m. between a moving strip of

sensitive paper and a spark-gap. Every time the spark jumps the

gap, that letter on the disc which happens to be at the time opposite

the gap is photographed ; 2,000 letters per minute may thus be recorded

on the moving tape, which passes through a developing and

fixing bath, out of which it emerges after about 9 seconds. To obtain

good results, the spark, it is said, must occur with a punctuality by

l/40000of a second, and this has been attained by a suitable arrangement

of condensers. The messages to be sent are first punched on

tape, which is then rapidly run through a rotating sender by means

of which corresponding current impulses in rapid succession are

sent to the line.—Lond. Elec, December 18.

Printing Telegraph Central Station.—Gradexwitz.—An illustrated

description of the tj'pe-printing telegraph service, recently added to

the Berlin telephone service. The instrument used is a teletypewriter

and the station is used at present to transmit exchange telegrams to

a certain number of subscribers. It is, therefore, in the nature of

our stock-ticker. The same system may, of course, be employed

for transmitting telegrams from a central telegraph office to a certain

number of newspaper offices.—Sc. Am., December 26.

April 9, 1904- ELECTRICAL WORLD and ENGINEER. 6&5

WASHINGTON UNDERGROUND WIRES.—A bill introduced

by Senator Gallinger and reported to the Senate with the recommendation

for favorable action by Senator Foraker from the Senate

Committee on the District of Columbia, requires all telegraph wires

in the District to be put under ground under penalty of a fine of

$25 per day.

GAMBLING BY TELEPHONE.—Mayor Harrison has appealed

to the Chicago Telephone Company for its co-operation in suppressing

pool rooms and "hand books". Warfare on tickers has

resulted in substituting telephones and the company finds itself in

the peculiar position of a common carrier obliged to accept and maintain

the secrecy of all business offered to it in ignorance of its purport,

and the operators are forbidden by the rules to listen in to

determine whether gambling is being conducted. Listening or "tapping

off" the line is in direct violation of the law.

|

|

Making a model 10

printer talk like a Teletype!

ARTS March 1955 issue, the one which has "GQ" and a

picture of a tape reader and

distributor on the cover and is #36. Starts on page

17. WHAT IS, AND WHO MADE MODEL 10?

ARTS - Amateur Radio Teletype Society History and

Bulletins

From the Jim Haynes, Red Wilson and Ed Sharpe collections at SMECC

can be found here: http://www.smecc.org/rtty_ratt_radio_teletype.htm

|

|

|

AWA BROAD TAPE STOCK NEWS TICKER

on display at the AWA museum.

Photo credit AWA.

Photo credit AWA.

Photo credit AWA.

Photo credit AWA.

Photo credit AWA.

Photo credit AWA.

Photo credit AWA.

Photo credit AWA.

Photo credit AWA.

Photo credit AWA.

Photo credit AWA.

|

|

|

|