|

T |

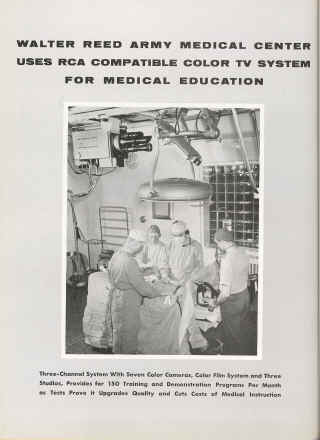

| The semiconductor industry with itís numerous spin-offs has been in existence long enough that we now are trying to chronicle the history. A number of articles document the technical progress. The advancement of the industry was and is accomplished by people who are dedicated to invention, technology, income, fame and a place in history. With all of those drives they yet are humans and have the foibles as well as successes. This article will help us recall the human side of the growth of this now very important industry. My viewpoint of the early days of the times around the introduction of semiconductors as replacements for vacuum tubes into the electronics industry is from RCA. The threat of some solid state thing taking the place of vacuum tubes made RCA management sit up and take notice. The company was in 1950 the dominant maker of vacuum tubes in the world. Add to that the fact that General David Sarnoff, president, board chairman, and spiritual leader was a technical visionary who could smell innovation and you will find the climate for invention. Witness the fact that RCA was very much present in global commercial record communications, sound on film for movies, television, color television, scanning electron microscopy and business oriented computers. It isnít too difficult to see that RCA had to get into the semiconductor business. The first effort from RCA was as a pimple on the tube business. Dr. Alan Glover was assigned to head the development of the technical competence as well as the business organization. The only proven semiconductor at the time was the point contact transistor. The technical brains at RCA decided to take an approach which was similar but an improvement. They would use a vertically oriented plate of single crystal germanium which would be the base and bring pointed wires from both sides into contact with the base. These wires were made of material which would provide dopant when fused to the base. My recollection was that the wires were phosphor-bronze. The wire furnished the required n+ material for compensating the boron (p) doping of the base material. The fusing of the wires was accomplished by discharge of a capacitor between emitter and base then collector and base. The machine which formed these junctions was then used to check DC forward current gain (beta). While touring the operation one day I watched the junction formation operators work. Beside each machine were two plastic buckets. The reject container was much larger than that for good parts. The potential transistors were encapsulated in clear plastic before junction formation. Apparently, the importance of light as a carrier generator wasnít of concern at that time. It wasnít long before RCA stopped making germanium transistors that way. RCA was good at promotion of itís products. When they were getting some yield of transistors from the production line mentioned in the previous paragraph they called a press conference at the RCA Princeton Research Center. The press representatives knew that the conference was for announcing the Corporationís entry into the semiconductor business. The basement auditorium was filled to capacity with press representatives. After the formal announcement there was a question and answer session. When one journalist asked what was the selling price of the transistors the room fell silent. That question was on everyoneís mind. Before the RCA guy could answer someoneís alarm wrist watch went off. That almost broke up the meeting. Sensing a need for a more in-depth commitment to the semiconductor business the company erected a plant in Somerville, New Jersey dedicated to building semiconductors. The building was one of the first designed especially for the unique needs of this budding industry. As early as the late 1950ís it was known that dust was an enemy. The electrostatic precipitators which handled the incoming air for the plant could be heard at the employees entrance to the plant. New Jersey was always humid and the zapping sparks could almost always be heard. I believe RCA chose Somerville because of itís proximity to Princeton where the RCA Research Labs were located. At the start of the semiconductor industry the government in the form of the Defense Department heavily influenced the direction the industry took. This was accomplished through research and development contracts and orders from manufacturers of electronic equipment utilizing semiconductors developed through government contracts. RCA obtained a contract for development of an automated production line for germanium alloy transistors. Each segment of the production line was well conceived and performed well. There was hardly any output from the line because it was difficult to have all elements of the line operable at the same time. That was the first time we realized the need for buffer storage between processes. In the semiconductor industry we learn often by our failures as well as our successes. The failures are simply "no" answers. One of the "no" answers which plagued RCA was whether to convert production from germanium to silicon. The armed forces were demanding silicon transistors because of their capability to operate at higher temperatures. Bell Labs had made some transistors using silicon. One astute marketer at RCA Semiconductor was asked to study and report his recommendations as to whether RCA should obtain capability for silicon semiconductors. His study showed that RCA should avoid the material because it would only be useful for military purposes. The armed forces ultimately would be only a small portion of the market. He was half right. That isnít good enough. He soon found himself out of the semiconductor industry and into steel fabrication such as that used for antenna towers. It could be argued that belief in that report caused RCAís ultimate small portion of the industry while Texas Instruments whole-heartedly embraced silicon and adapted itself to the technology which followed the point contact transistor. For silicon that was the grown junction transistor. It was a really difficult technology to operate but did advance the industry into the high frequency realm. One of the earliest if not the earliest transistor portable broadcast frequency radio was made by the famous watchmaker, Bulova. The radio used transistors from the 2N135 series which were all grown junction. One advantage of the grown junction transistor was that the base could theoretically be made only a few lattices thick allowing the bulk of the minority carriers to transit the base before recombination occurred. In practice it wasnít that easy. Scientists at Lansdale Transistor, a division of Philco, including a young engineer named Clare Thornton found another way of creating thin base sections. They electro-chemically etched the slab of germanium which was to be the base. A jet of chemical etchant with an electrical bias was aimed at both sides of the slab. When the plate of single crystal germanium was thin enough (translucent to visible light) the etching was stopped and emitter and collector wires were alloyed to the slab. While this was also a difficult to control process it did produce transistors which could operate with reasonable gains beyond 30 MHz. These transistors were incorporated into the AN/PRC 25 back pack radio of Korean War fame. Millions of these transistors were used even though Lansdale faded from the scene to be replaced by a licensee, Sprague. Later, Motorola with a somewhat more forgiving process, mesa construction, supplied the bulk of the military and industrial needs. Dr. Thornton is presently with the Army Electronics Research and Development Command heading the organization which explores the latest concepts in future semiconductor uses. RCAís role in development of color television was unique. When the demand for color television developed, there were two protagonists. These were CBS and RCA. The CBS system was under the direction of Dr. Peter Goldmark. RCAís guru was Dr. Al Goldsmith. These two scientists were like a stray cat and a bull dog. Dr. Goldsmith thought Dr. Goldmark intellectually dishonest ( I quote him) and Dr. Goldmark had similar thoughts about Al Goldsmith. The Federal Communications Commission (FCC) after some demands by industry proposed competitive demonstrations of all systems which would be demonstrated in Washington, DC. The CBS system used a large (usually larger than three feet in diameter ) spinning disk between the scene and the camera tube. The normal camera tube at that time was the Image Orthicon. The disc contained a spiral series of lenses and sequential color filters. The receiver and to a lesser extent the disk at home duplicated the studio setup. Color fields were sent sequentially and synchronizing between transmitter and receiver were necessary to have the correct color filter over the picture tube at the correct moment. The system had one great advantage. It was compatible with existing black and white television receivers. Since they didnít receive or need the color information they performed as they had before. The major disadvantage was that at that time the sequential color filters needed to be the same size as the picture tube. Imagine a disk containing sequential red, green and blue filters of 14" diagonal rotating so that the three colors were presented over the black and white tube every 1/30th of a second. RCA demonstrated a large cabinet which contained three separate picture tubes, dichroic filters and mirrors. The images were superimposed to create a color picture. The system wasnít compatible with anything. The FCC opted for the CBS system and that was the color TV standard for a year or more. When General Sarnoff heard the FCC decision he called Dr. Goldsmith by telephone and said "invent color television". That story comes from Dr. Goldsmith and is believable. As Al related the story, he spent all day thinking of the ways to present color information and listed about 17. His concern was with the color picture tube. After sleeping on the ideas he narrowed his choices to the four which in his mind were the most viable. Those RCA filed as patent applications. One of the four was the three gun shadow mask system which is still today the dominant picture tube type. The color tube was being perfected, first as a 15" metal to glass tube and later 21" metal to glass. Despite careful selection of materials there remained a difference of linear expansion coefficient between the glass and the steel of the envelope. With the heat cycling caused by turning the set on and off some tubes became leaky and would no longer support the generation of the three electron beams. The first rectangular all glass color picture tube was a marvel of technology. The face plate with itís screened on triads of colors of phosphors and the precision etched shadow mask was manufactured then mated to the guns and accelerating portion of the envelope. Lancaster, Pennsylvania was the fountain head of this development. Most of the potential manufacturers of color television sets joined in a voluntary cooperative organization called the National Television Standards Committee (NTSC). They did a very careful job of specifying how a color television system could function as an adjunct to the existing US black and white television system. That system utilized 525 horizontal lines per frame with half the lines in each field of one sixtieth (almost) of a second. Alternating fields contained odd and even numbers of the 525 lines. Thus each 1/30th of a second contained a complete picture with interlaced horizontal scanning. The transmission of the video signal by radio involved truncating almost all of one side band (now called vestigial sideband transmission). The bandwidth of the remaining sideband was 4.5 MHz wide. The NTSC members found by analysis that there was little or no information transmitted near the 4.5 MHz limit. They decided to place the color information on a subcarrier between where information was transmitted near the limit of the band. That subcarrier was placed 3.579 MHz (plus some further significant numbers) above the carrier. The subcarrier was modulated with color information in a very compact form. To technically describe a color requires knowledge of luminance (brightness) and chrominance (color on an absolute scale). Chrominance is further divided in to itís two attributes, hue (color temperature) and saturation (intensity of color in gray). The NTSC members knew that the CBS system would not survive the need for improvements and so petitioned the FCC to reconsider itís decision to authorize the spinning wheel color system. The FCC after many hearings reversed itís previous decision and opted for the NTSC system. And color television started in earnest. One early user of color television was to be the Armed Forces Institute of Pathology (AFIP). This organization was to be the source of pathological information for all of the armed services as well as the teaching organization for military pathologists. Plans called for the ability to provide color television views of pathology and pathological procedures in all class rooms as well as the ability to transmit such information by normal cable and microwave routes throughout the world. The building is located on the grounds of the Walter Reed Army Hospital in Washington, DC. It was almost completed when the time came for selection of a color television system. Because the television was for the most part closed circuit the compatibility issue was not paramount. The Colonel who was head of the AFIP decided to hold a technical conference at the Institute to explore the uses of color television in pathology and at the same time allow demonstrations of the competing systems so that a system could be selected for installation in the building. The schedule called for two days of presentations and demonstrations. The first day was to be the big one. Dr. Al Goldsmith was to be the featured speaker in the late morning followed by Dr. Peter Goldmark. Goldsmith was naturally in favor of the NTSC System having been the inventor of the shadow mask type of picture tube. Just as avid about the CBS system was Peter Goldmark. Dr. Goldsmith on hearing the speaking order refused to appear. After some behind the scenes consultation Dr. Goldsmith and I obtained sandwiches and soft drink for me and milk for him. We found a closet almost full of lumber and hid locking the door while we ate lunch. Sitting on the unfinished splintery lumber was not exactly like a gourmet restaurant but it did accomplish the purpose. Dr. Goldmark did give his presentation before lunch. Dr. Goldsmith reappeared at 1 PM and gave his talk. Later demonstrations by CBS and RCA were useful in allowing the AFIP to decide which color TV system would be used. RCA went all out by presentation of an operation for suspected breast cancer in Philadelphia. The nodule removed from the breast was frozen, microtomed and stained. The stained sample was shown in color through a microscope. Pathologists in Baltimore examined the video picture sent by cable and decided the nodule indicated carcinoma. We in Washington could see the operation and both sides of the discussion between the surgeon and the pathologists. At the opposite end of the scale of what can you do with color TV was a film about the necropsy of a young elephant from the Washington zoo. Necropsy is the same for animals as autopsy is for humans. The tools though instead of scalpels are butcher knives and axes. The 28 year old elephant apparently died of a lung disease. The doctors at the Armed Forces Institute of Pathology did decide that the NTSC system was likely to live longer than the CBS system and chose to equip their facility with the compatible system. These stories show that progress is created by humans who are dissatisfied with the state of things. The Texans have an appropriate saying "Fat dogs donít hunt." More of the human side of technological progress will be related in future issues. -IRS

And indeed it was accepted and used all over Walter Reed!

|

|

ABOUT IVAN R. SADDLER |

| Mr. Saddler is a noted expert in the field of microelectronics. He has been active in the field since 1952. His experience includes several years experience in a tube and semiconductor manufacturing organization; management of a hybrid microcircuit company for several years; work in semiconductor companies for 29 years and; presently assistant professor at Arizona State University. EDUCATION BSEE degree University of Texas at El Paso 1950 George Washington University Law School 1951-1952 Motorola Executive Institute - 1974 Graduate Gemmologist-Gemmological Institute of America-1981 SERVICE IN BUSINESS RCA Semiconductor 1952-1962 Various sales, marketing and contract management primarily with U.S. government. Microlectron, Inc. 1962-1964 V.P. and General Manager. Manufacture of thick film hybrid microcircuits. Motorola Semiconductor Products Sector 1964-1982 Management positions relating to U. S. government research and development in the semiconductor field; patent technology and; management of the Very High Speed Integrated Circuit ( VHSIC ) program; a $37 m research and development program in VLSI. PROFESSIONAL ACTIVITIES Three issued patents in the semiconductor field. Membership in Arizona Electrostatic Discharge Society Membership in Society of Manufacturing Engineers Member of International Society of Hybrid Microcircuits Numerous articles and papers including: Microprocessors Vs. Custom ICs-Military Electronics Countermeasures June Ď77 Can VLSI Growth Continue? Military Electronics Countermeasures Feb. Ď80 The Future of VLSI in Our Defense-with Chas. Meyer GOMAC Conf. Nov. Ď80 Engineers for VLSI-A Scarce Commodity-IEEE Transactions on Components, Hybrids and Manufacturing Technology-Mar.í82 The Challenge of Education for VLSI-with W. G. Howard- VLSI Electronics Microstructure Science Vol. 4-Apr. Ď81 The Challenge of Education for VLSI-with W. G. Howard- VLSI Electronics Microstructure Science Vol. 4-Apr. Ď81 HONORS Listed in Whoís Who in the West Listed in Whoís Who in America Listed in Whoís Who in Technology

|